| Availability: | |

|---|---|

What is boiler tube

The boiler tube is a branch pipe of the seamless steel pipe. It is used for boiler, heat-exchanger, or superheater. It has stringent requirements for the manufacture of steel pipes. According to the working temperature. It can be divided into general boiler tubes and high-pressure boiler tubes. Some of the boiler pipes are made of carbon steel and alloy steel. Both carbon steel boiler tubes and alloy steel boiler tubes have different usage situations and temperature situations.

How are boiler tubes made?

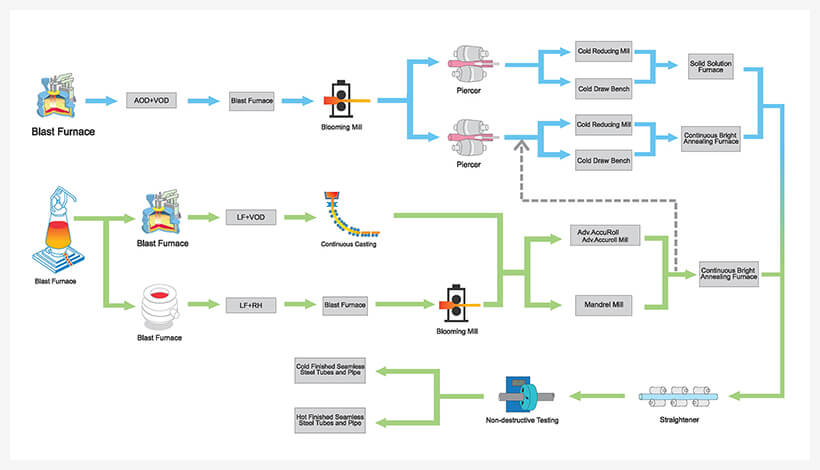

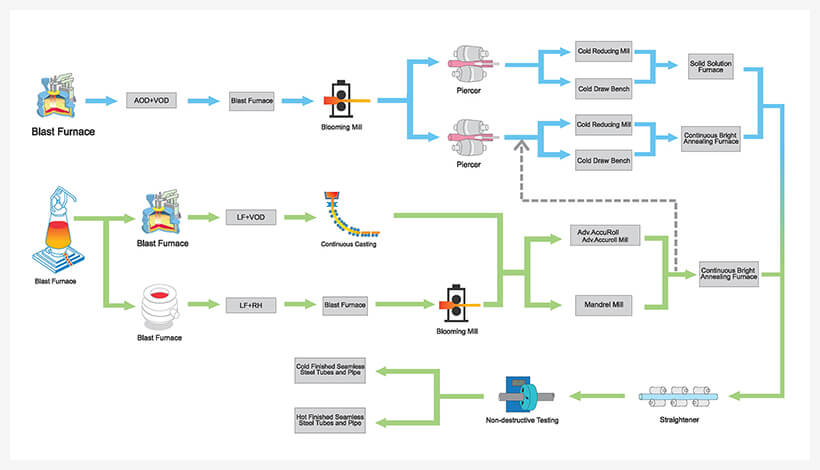

Both medium-pressure and high-pressure boiler tubes undergo the same initial process of manufacturing, which includes fine drawing, surface bright, hot rolling, cold drawn and heat expansion. However, the following steps are undertaken to make high-pressure pipes stronger and more resistant.

Heat treatment includes heating and cooling of the high-pressure boiler pipes which increases toughness, hardness and wear resistance. The different steps that come under heat treatment include quenching, tempering and annealing.

Quenching is done to increase the hardness of the high-pressure boiler tube. The pipe is heated evenly to an appropriate temperature and then quickly immersed into water or oil for instant cooling. This is followed by cooling in air or in the freezing zone.

Tempering is used to remove brittleness from the pipe. Quenching can cause the pipe to become tapped or broken.

Annealing can remove the internal stress in the pipe. In this process, the seamless tube is heated to the critical temperature and then left for slow cooling in ash or lime.

How to choose good quality boiler tubes?

While choosing boiler tubes, look for the following to pick out the right and good quality tubes:

1. Look at the cross-section of the tube. A good quality seamless tube will have a smooth cross-section and will be devoid of bumps and irregularities.

2. Check the density of the pipe to understand the percentage of impurities in the pipe. If the pipe shows low density, steer clear!

3. Make sure you check the trademark. Reputed manufacturers always put their trademark on their seamless tubes.

4. Check the surface of the boiler tube. A good quality boiler tube will have a smooth surface. If you find the surface to be rough and uneven, you can be sure that the quality is not up to the mark.

What is boiler tube

The boiler tube is a branch pipe of the seamless steel pipe. It is used for boiler, heat-exchanger, or superheater. It has stringent requirements for the manufacture of steel pipes. According to the working temperature. It can be divided into general boiler tubes and high-pressure boiler tubes. Some of the boiler pipes are made of carbon steel and alloy steel. Both carbon steel boiler tubes and alloy steel boiler tubes have different usage situations and temperature situations.

How are boiler tubes made?

Both medium-pressure and high-pressure boiler tubes undergo the same initial process of manufacturing, which includes fine drawing, surface bright, hot rolling, cold drawn and heat expansion. However, the following steps are undertaken to make high-pressure pipes stronger and more resistant.

Heat treatment includes heating and cooling of the high-pressure boiler pipes which increases toughness, hardness and wear resistance. The different steps that come under heat treatment include quenching, tempering and annealing.

Quenching is done to increase the hardness of the high-pressure boiler tube. The pipe is heated evenly to an appropriate temperature and then quickly immersed into water or oil for instant cooling. This is followed by cooling in air or in the freezing zone.

Tempering is used to remove brittleness from the pipe. Quenching can cause the pipe to become tapped or broken.

Annealing can remove the internal stress in the pipe. In this process, the seamless tube is heated to the critical temperature and then left for slow cooling in ash or lime.

How to choose good quality boiler tubes?

While choosing boiler tubes, look for the following to pick out the right and good quality tubes:

1. Look at the cross-section of the tube. A good quality seamless tube will have a smooth cross-section and will be devoid of bumps and irregularities.

2. Check the density of the pipe to understand the percentage of impurities in the pipe. If the pipe shows low density, steer clear!

3. Make sure you check the trademark. Reputed manufacturers always put their trademark on their seamless tubes.

4. Check the surface of the boiler tube. A good quality boiler tube will have a smooth surface. If you find the surface to be rough and uneven, you can be sure that the quality is not up to the mark.

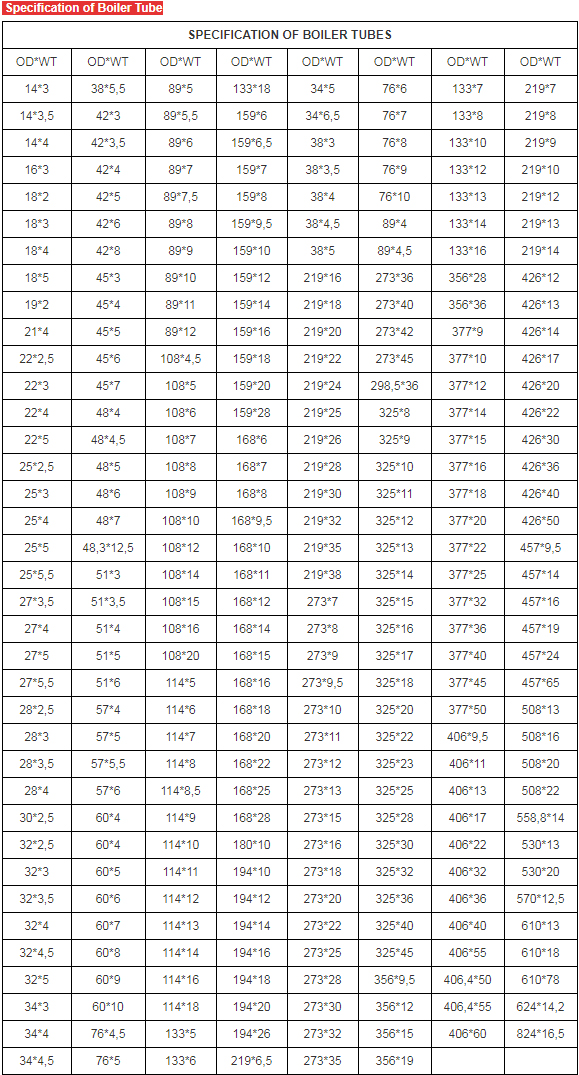

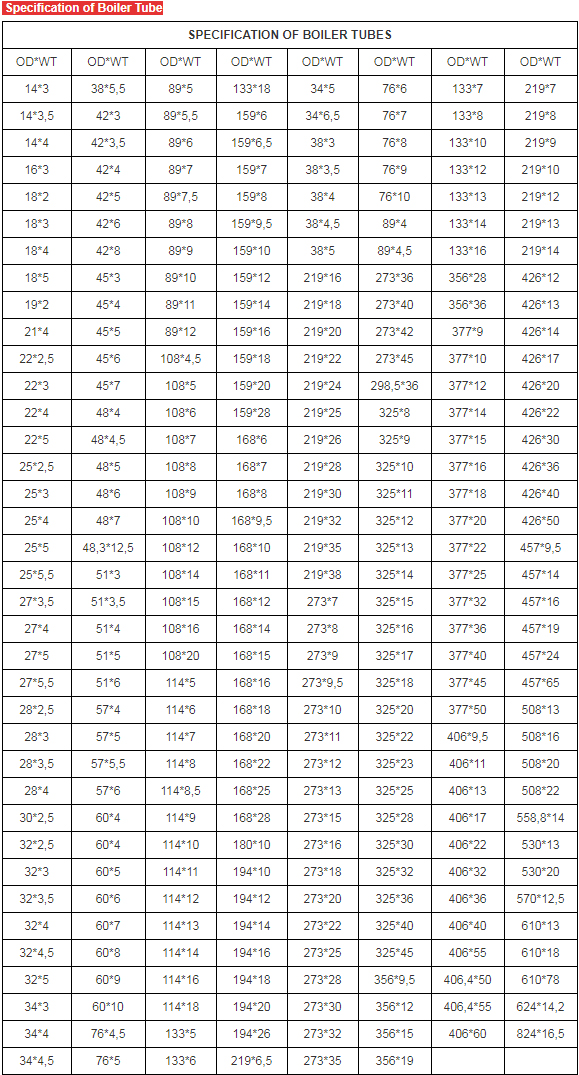

Size of boiler tube

Size of boiler tube

Manufacturing process of boiler tube

Manufacturing process of boiler tube

Standard of boiler tube

Outer Diameter Tolerances | ||

Standard | Outer Diameter | Tolerance |

GB3087 | ≤180 | ±1.0% |

GB5310 | ≤50 | ±0.5mm |

>50 | ±1.0% | |

Wall Thickness Tolerances | ||

Standard | Wall Thickness(mm) | Tolerance |

GB3087 | 3-20 | +15%,12.5% |

>20 | ±12.5% | |

GB5310 | <3.5 | +15%,-10% |

3.5-20 | +15%,-10% | |

>20 | ±10% | |

Chemical composition and mechanical properties | |||||||||

Standard | Grade | Chemical composition(%) | Mechanical properties | ||||||

C | Si | Mn | P | S | Tensile Strength | Yield Strength | Elongation | ||

DIN17175 | St35.8 | ≤0.17 | 0.10-0.35 | 0.40-0.80 | ≤0.030 | ≤0.030 | 360-480 | ≥235 | ≥25 |

St45.8 | ≤0.21 | 0.10-0.35 | 0.40-1.20 | ≤0.030 | ≤0.030 | 410-530 | ≥255 | ≥21 | |

Standard of boiler tube

Outer Diameter Tolerances | ||

Standard | Outer Diameter | Tolerance |

GB3087 | ≤180 | ±1.0% |

GB5310 | ≤50 | ±0.5mm |

>50 | ±1.0% | |

Wall Thickness Tolerances | ||

Standard | Wall Thickness(mm) | Tolerance |

GB3087 | 3-20 | +15%,12.5% |

>20 | ±12.5% | |

GB5310 | <3.5 | +15%,-10% |

3.5-20 | +15%,-10% | |

>20 | ±10% | |

Chemical composition and mechanical properties | |||||||||

Standard | Grade | Chemical composition(%) | Mechanical properties | ||||||

C | Si | Mn | P | S | Tensile Strength | Yield Strength | Elongation | ||

DIN17175 | St35.8 | ≤0.17 | 0.10-0.35 | 0.40-0.80 | ≤0.030 | ≤0.030 | 360-480 | ≥235 | ≥25 |

St45.8 | ≤0.21 | 0.10-0.35 | 0.40-1.20 | ≤0.030 | ≤0.030 | 410-530 | ≥255 | ≥21 | |

Application of boiler tube

Steam Boilers

Power Generation

Fossil Fuel Plants

Electric Power Plants

Industrial Process Plants

Co generation Facilities

Application of boiler tube

Steam Boilers

Power Generation

Fossil Fuel Plants

Electric Power Plants

Industrial Process Plants

Co generation Facilities

About Us / News / Product / Project / Quality Assurance / Service / Contact Us