| Availability: | |

|---|---|

What is API 5L pipe

API 5L pipe for pipeline transportation systems in the petroleum and natural gas industries. This steel pipe is suitable for conveying gas, water, and oil. It covers PSL1, PSL2, Sour Services, for onshore and offshore pipelines. Manufacturing types including seamless and welded. PSL1 generally uses which equivalent to ASTM A106 B and A53 B. PSL2 is a higher specification level pipe, has more strict value on chemical and mechanical strength. Moreover, PSL2 requires more test methods. API 5L B PSL2 expressed with API 5L BN/Q/R/M. Sour Services: For sour pipelines like H2S environment, pipe material have typical restrictions on chemicals element of Carbon, P and S. API 5L B Pipe for Sour Service expressed in API 5L BNS/QS/MS

What is API 5L pipe

API 5L pipe for pipeline transportation systems in the petroleum and natural gas industries. This steel pipe is suitable for conveying gas, water, and oil. It covers PSL1, PSL2, Sour Services, for onshore and offshore pipelines. Manufacturing types including seamless and welded. PSL1 generally uses which equivalent to ASTM A106 B and A53 B. PSL2 is a higher specification level pipe, has more strict value on chemical and mechanical strength. Moreover, PSL2 requires more test methods. API 5L B PSL2 expressed with API 5L BN/Q/R/M. Sour Services: For sour pipelines like H2S environment, pipe material have typical restrictions on chemicals element of Carbon, P and S. API 5L B Pipe for Sour Service expressed in API 5L BNS/QS/MS

Size chart of API 5L pipe

NPS | Outside Diameter | API 5l Pipe Schedule | ||||||||||||

SCH 10 | SCH 20 | SCH 30 | SCH STD | SCH 40 | SCH 60 | SCH XS | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | SCH XXS | ||

Wall Thickness (in) | ||||||||||||||

1/8 | 0.405 | 0.068 | 0.068 | 0.095 | 0.095 | |||||||||

1/4 | 0.54 | 0.088 | 0.088 | 0.119 | 0.119 | |||||||||

3/8 | 0.675 | 0.091 | 0.091 | 0.126 | 0.126 | |||||||||

1/2 | 0.84 | 0.109 | 0.109 | 0.147 | 0.147 | 0.187 | 0.294 | |||||||

3/4 | 1.05 | 0.113 | 0.113 | 0.154 | 0.154 | 0.219 | 0.308 | |||||||

1 | 1.315 | 0.133 | 0.133 | 0.179 | 0.179 | 0.25 | 0.358 | |||||||

1 1/4 | 1.66 | 0.14 | 0.14 | 0.191 | 0.191 | 0.25 | 0.382 | |||||||

1 1/2 | 1.9 | 0.145 | 0.145 | 0.2 | 0.2 | 0.281 | 0.4 | |||||||

2 | 2.375 | 0.154 | 0.154 | 0.218 | 0.218 | 0.344 | 0.436 | |||||||

2 1/2 | 2.875 | 0.203 | 0.203 | 0.276 | 0.276 | 0.375 | 0.552 | |||||||

3 | 3.5 | 0.216 | 0.216 | 0.3 | 0.3 | 0.438 | 0.6 | |||||||

3 1/2 | 4 | 0.226 | 0.226 | 0.318 | 0.318 | |||||||||

4 | 4.5 | 0.237 | 0.237 | 0.337 | 0.337 | 0.438 | 0.531 | 0.674 | ||||||

5 | 5.563 | 0.258 | 0.258 | 0.375 | 0.375 | 0.5 | 0.625 | 0.75 | ||||||

6 | 6.625 | 0.28 | 0.28 | 0.432 | 0.432 | 0.562 | 0.719 | 0.864 | ||||||

8 | 8.625 | 0.25 | 0.277 | 0.322 | 0.322 | 0.406 | 0.5 | 0.5 | 0.594 | 0.719 | 0.812 | 0.906 | 0.875 | |

10 | 10.75 | 0.25 | 0.307 | 0.365 | 0.365 | 0.5 | 0.5 | 0.594 | 0.719 | 0.844 | 1 | 1.125 | 1 | |

12 | 12.75 | 0.25 | 0.33 | 0.375 | 0.406 | 0.562 | 0.5 | 0.688 | 0.844 | 1 | 1.125 | 1.312 | 1 | |

14 | 14 | 0.25 | 0.312 | 0.375 | 0.375 | 0.438 | 0.594 | 0.5 | 0.75 | 0.938 | 1.094 | 1.25 | 1.406 | |

16 | 16 | 0.25 | 0.312 | 0.375 | 0.375 | 0.5 | 0.656 | 0.5 | 0.844 | 1.031 | 1.219 | 1.438 | 1.594 | |

18 | 18 | 0.25 | 0.312 | 0.438 | 0.375 | 0.562 | 0.75 | 0.5 | 0.938 | 1.156 | 1.375 | 1.562 | 1.781 | |

20 | 20 | 0.25 | 0.375 | 0.5 | 0.375 | 0.594 | 0.812 | 0.5 | 1.031 | 1.281 | 1.5 | 1.75 | 1.969 | |

22 | 22 | 0.25 | 0.375 | 0.5 | 0.375 | 0.875 | 0.5 | 1.125 | 1.375 | 1.625 | 1.875 | 2.125 | ||

24 | 24 | 0.25 | 0.375 | 0.562 | 0.375 | 0.688 | 0.969 | 0.5 | 1.219 | 1.531 | 1.812 | 2.062 | 2.344 | |

30 | 30 | 0.312 | 0.5 | 0.625 | 0.375 | 0.5 | ||||||||

32 | 32 | 0.312 | 0.5 | 0.625 | 0.375 | 0.688 | ||||||||

34 | 34 | 0.312 | 0.5 | 0.625 | 0.375 | 0.688 | ||||||||

36 | 36 | 0.312 | 0.5 | 0.625 | 0.375 | 0.75 | ||||||||

42 | 42 | 0.5 | 0.625 | 0.375 | 0.75 | |||||||||

Size chart of API 5L pipe

NPS | Outside Diameter | API 5l Pipe Schedule | ||||||||||||

SCH 10 | SCH 20 | SCH 30 | SCH STD | SCH 40 | SCH 60 | SCH XS | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | SCH XXS | ||

Wall Thickness (in) | ||||||||||||||

1/8 | 0.405 | 0.068 | 0.068 | 0.095 | 0.095 | |||||||||

1/4 | 0.54 | 0.088 | 0.088 | 0.119 | 0.119 | |||||||||

3/8 | 0.675 | 0.091 | 0.091 | 0.126 | 0.126 | |||||||||

1/2 | 0.84 | 0.109 | 0.109 | 0.147 | 0.147 | 0.187 | 0.294 | |||||||

3/4 | 1.05 | 0.113 | 0.113 | 0.154 | 0.154 | 0.219 | 0.308 | |||||||

1 | 1.315 | 0.133 | 0.133 | 0.179 | 0.179 | 0.25 | 0.358 | |||||||

1 1/4 | 1.66 | 0.14 | 0.14 | 0.191 | 0.191 | 0.25 | 0.382 | |||||||

1 1/2 | 1.9 | 0.145 | 0.145 | 0.2 | 0.2 | 0.281 | 0.4 | |||||||

2 | 2.375 | 0.154 | 0.154 | 0.218 | 0.218 | 0.344 | 0.436 | |||||||

2 1/2 | 2.875 | 0.203 | 0.203 | 0.276 | 0.276 | 0.375 | 0.552 | |||||||

3 | 3.5 | 0.216 | 0.216 | 0.3 | 0.3 | 0.438 | 0.6 | |||||||

3 1/2 | 4 | 0.226 | 0.226 | 0.318 | 0.318 | |||||||||

4 | 4.5 | 0.237 | 0.237 | 0.337 | 0.337 | 0.438 | 0.531 | 0.674 | ||||||

5 | 5.563 | 0.258 | 0.258 | 0.375 | 0.375 | 0.5 | 0.625 | 0.75 | ||||||

6 | 6.625 | 0.28 | 0.28 | 0.432 | 0.432 | 0.562 | 0.719 | 0.864 | ||||||

8 | 8.625 | 0.25 | 0.277 | 0.322 | 0.322 | 0.406 | 0.5 | 0.5 | 0.594 | 0.719 | 0.812 | 0.906 | 0.875 | |

10 | 10.75 | 0.25 | 0.307 | 0.365 | 0.365 | 0.5 | 0.5 | 0.594 | 0.719 | 0.844 | 1 | 1.125 | 1 | |

12 | 12.75 | 0.25 | 0.33 | 0.375 | 0.406 | 0.562 | 0.5 | 0.688 | 0.844 | 1 | 1.125 | 1.312 | 1 | |

14 | 14 | 0.25 | 0.312 | 0.375 | 0.375 | 0.438 | 0.594 | 0.5 | 0.75 | 0.938 | 1.094 | 1.25 | 1.406 | |

16 | 16 | 0.25 | 0.312 | 0.375 | 0.375 | 0.5 | 0.656 | 0.5 | 0.844 | 1.031 | 1.219 | 1.438 | 1.594 | |

18 | 18 | 0.25 | 0.312 | 0.438 | 0.375 | 0.562 | 0.75 | 0.5 | 0.938 | 1.156 | 1.375 | 1.562 | 1.781 | |

20 | 20 | 0.25 | 0.375 | 0.5 | 0.375 | 0.594 | 0.812 | 0.5 | 1.031 | 1.281 | 1.5 | 1.75 | 1.969 | |

22 | 22 | 0.25 | 0.375 | 0.5 | 0.375 | 0.875 | 0.5 | 1.125 | 1.375 | 1.625 | 1.875 | 2.125 | ||

24 | 24 | 0.25 | 0.375 | 0.562 | 0.375 | 0.688 | 0.969 | 0.5 | 1.219 | 1.531 | 1.812 | 2.062 | 2.344 | |

30 | 30 | 0.312 | 0.5 | 0.625 | 0.375 | 0.5 | ||||||||

32 | 32 | 0.312 | 0.5 | 0.625 | 0.375 | 0.688 | ||||||||

34 | 34 | 0.312 | 0.5 | 0.625 | 0.375 | 0.688 | ||||||||

36 | 36 | 0.312 | 0.5 | 0.625 | 0.375 | 0.75 | ||||||||

42 | 42 | 0.5 | 0.625 | 0.375 | 0.75 | |||||||||

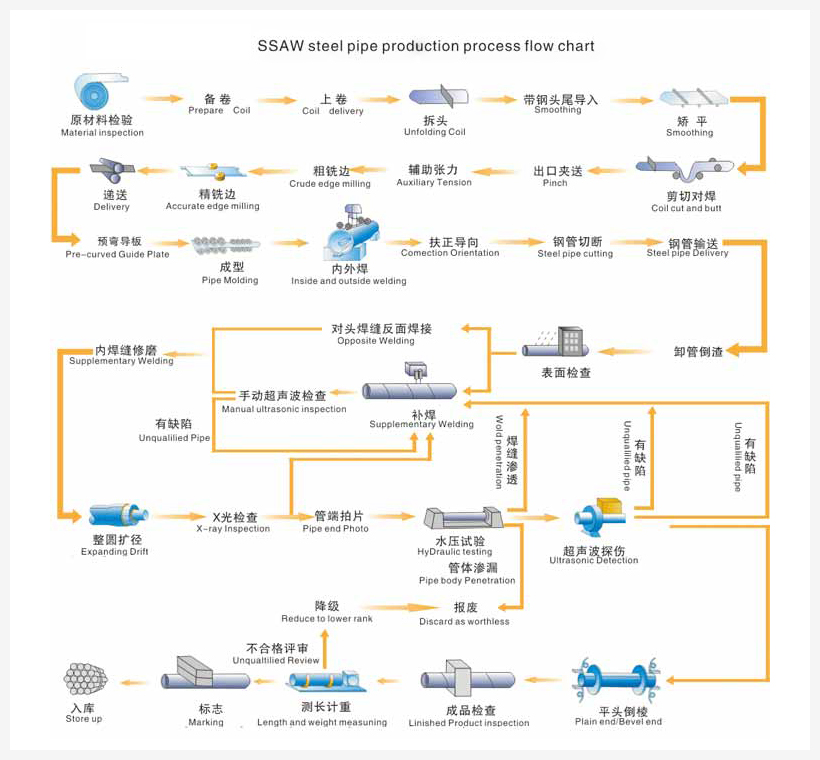

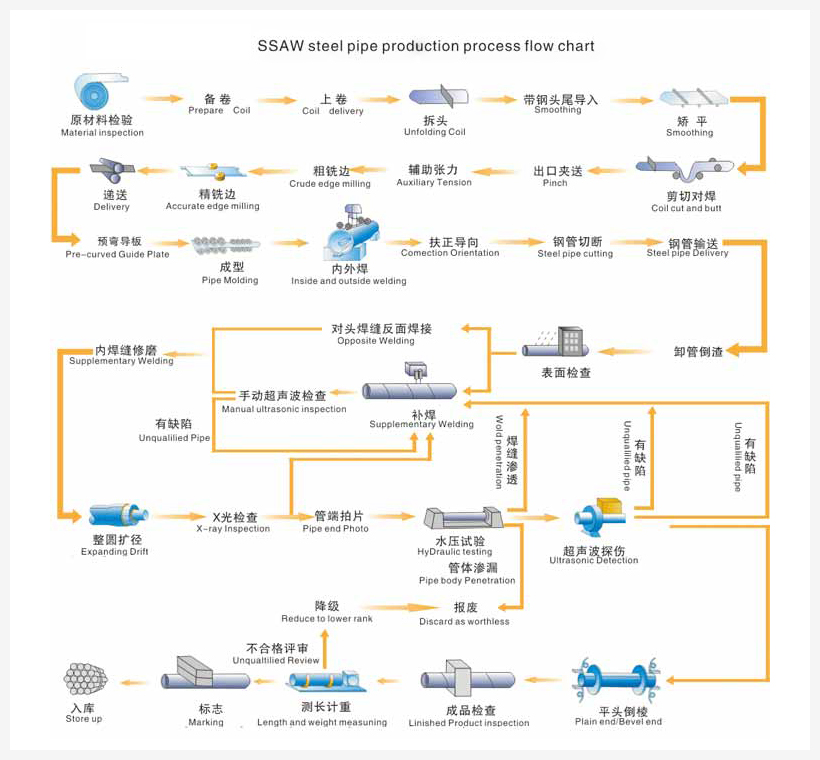

Manufacturing process of API 5L pipe

Manufacturing process of API 5L pipe

Standard of API 5L pipe

Dimensional tolerances | ||||||

Standard | Outer diameter tolerance | Wall thickness tolerance | ||||

A25.A.B | X42-X70 | |||||

D<60.3 | +0.41/-0.40mm | D<73 | -160 | D≥73 | -120 | |

API SPEC 5L | D≥60.3 | +0.75/-0.40mm | D≥73 | -120 | D>73 | -120 |

Mechanical properties | ||||||

Standard | Grade | Yield strength (MPa) | Tensile strength (MPa) | Elongation | ||

API SPEC 5L | PSL1 | |||||

A25 | 172 | 310 | ||||

A | 207 | 331 | ||||

B | 241 | 414 | ||||

X42 | 290 | 414 | ||||

X46 | 317 | 434 | ||||

X52 | 359 | 455 | ||||

X56 | 386 | 490 | ||||

X60 | 414 | 517 | ||||

X65 | 448 | 531 | ||||

X70 | 483 | 565 | ||||

PSL2 | ||||||

Min | Max | Min | Max | |||

B | 241 | 448 | 414 | 758 | ||

X42 | 290 | 496 | 414 | 758 | ||

X46 | 317 | 524 | 434 | 758 | ||

X52 | 359 | 531 | 455 | 758 | ||

X56 | 386 | 544 | 490 | 758 | ||

X60 | 414 | 565 | 517 | 758 | ||

X65 | 448 | 600 | 531 | 758 | ||

X70 | 483 | 621 | 565 | 758 | ||

X80 | 552 | 690 | 621 | 827 | ||

Chemical composition | ||||||

Standard | Grade | C | Mn | P | S | |

Max | Max | Min | Max | Max | ||

API SPEC 5L | PSL1 | |||||

A25II | 0.21 | 0.6 | 0.03 | 0.03 | ||

A25III | 0.21 | 0.6 | 0.45 | 0.8 | 0.03 | |

A | 0.22 | 0.9 | 0.03 | 0.03 | ||

B | 0.28 | 1.2 | 0.03 | 0.03 | ||

X42 | 0.28 | 1.3 | 0.03 | 0.03 | ||

X46.X52.X56 | 0.28 | 1.4 | 0.03 | 0.03 | ||

X60.X65.X70 | 0.28 | 1.4 | 0.03 | 0.03 | ||

PSL2 | ||||||

B | 0.24 | 1.2 | 0.025 | 0.015 | ||

X42 | 0.24 | 1.3 | 0.025 | 0.015 | ||

X46.X52.X56 | 0.24 | 1.4 | 0.025 | 0.015 | ||

X60.X65.X70.X80 | 0.24 | 1.4 | 0.025 | 0.015 | ||

Standard of API 5L pipe

Dimensional tolerances | ||||||

Standard | Outer diameter tolerance | Wall thickness tolerance | ||||

A25.A.B | X42-X70 | |||||

D<60.3 | +0.41/-0.40mm | D<73 | -160 | D≥73 | -120 | |

API SPEC 5L | D≥60.3 | +0.75/-0.40mm | D≥73 | -120 | D>73 | -120 |

Mechanical properties | ||||||

Standard | Grade | Yield strength (MPa) | Tensile strength (MPa) | Elongation | ||

API SPEC 5L | PSL1 | |||||

A25 | 172 | 310 | ||||

A | 207 | 331 | ||||

B | 241 | 414 | ||||

X42 | 290 | 414 | ||||

X46 | 317 | 434 | ||||

X52 | 359 | 455 | ||||

X56 | 386 | 490 | ||||

X60 | 414 | 517 | ||||

X65 | 448 | 531 | ||||

X70 | 483 | 565 | ||||

PSL2 | ||||||

Min | Max | Min | Max | |||

B | 241 | 448 | 414 | 758 | ||

X42 | 290 | 496 | 414 | 758 | ||

X46 | 317 | 524 | 434 | 758 | ||

X52 | 359 | 531 | 455 | 758 | ||

X56 | 386 | 544 | 490 | 758 | ||

X60 | 414 | 565 | 517 | 758 | ||

X65 | 448 | 600 | 531 | 758 | ||

X70 | 483 | 621 | 565 | 758 | ||

X80 | 552 | 690 | 621 | 827 | ||

Chemical composition | ||||||

Standard | Grade | C | Mn | P | S | |

Max | Max | Min | Max | Max | ||

API SPEC 5L | PSL1 | |||||

A25II | 0.21 | 0.6 | 0.03 | 0.03 | ||

A25III | 0.21 | 0.6 | 0.45 | 0.8 | 0.03 | |

A | 0.22 | 0.9 | 0.03 | 0.03 | ||

B | 0.28 | 1.2 | 0.03 | 0.03 | ||

X42 | 0.28 | 1.3 | 0.03 | 0.03 | ||

X46.X52.X56 | 0.28 | 1.4 | 0.03 | 0.03 | ||

X60.X65.X70 | 0.28 | 1.4 | 0.03 | 0.03 | ||

PSL2 | ||||||

B | 0.24 | 1.2 | 0.025 | 0.015 | ||

X42 | 0.24 | 1.3 | 0.025 | 0.015 | ||

X46.X52.X56 | 0.24 | 1.4 | 0.025 | 0.015 | ||

X60.X65.X70.X80 | 0.24 | 1.4 | 0.025 | 0.015 | ||

Application of API 5L pipe

High technology and high value-added product

Metallurgy field

High-pressure gas transportation

High cold and corrosion service

Application of API 5L pipe

High technology and high value-added product

Metallurgy field

High-pressure gas transportation

High cold and corrosion service

About Us / News / Product / Project / Quality Assurance / Service / Contact Us