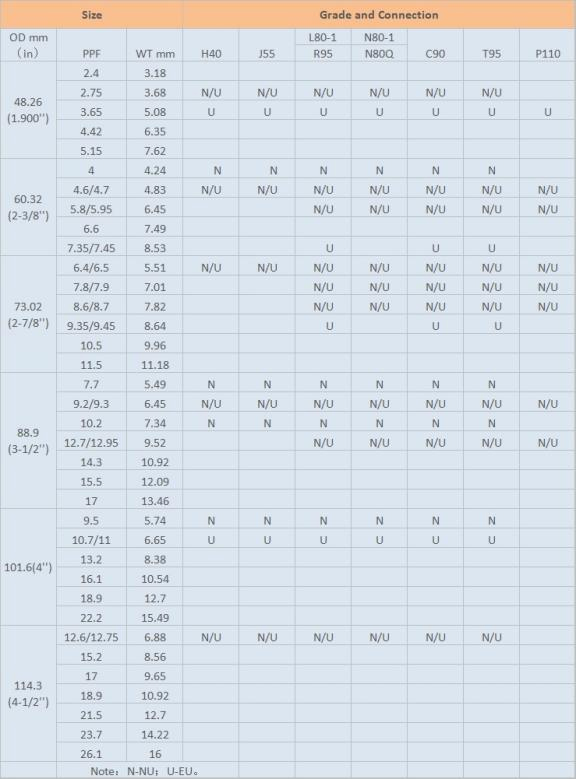

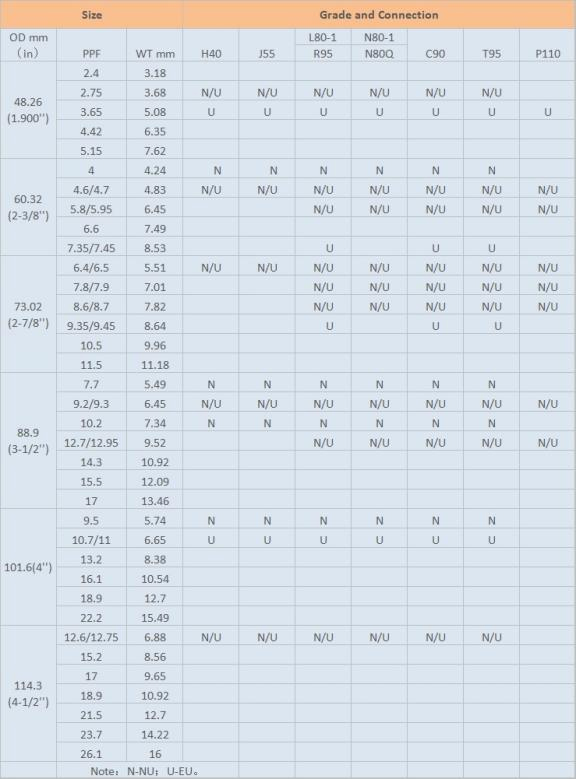

| Availability: | |

|---|---|

What is API tubing

API tubing is used to transport crude oil or natural gas from the layer of the oil and natural gas to surface. It has better pressure during oil or gas production and smaller diameters. When the tubing runs into a well to serve as a conduit for the oil and gas. It can withstand the pressure when the energy extraction process. Tubing can adequately resist loads and deformations associated with production and workovers. The manufacturing process same as casing. But it has added a manufacturing process to thicken the tubing.

Tubing is specified by grade, outer diameter, weight, and connection. API tubing grades correspond to casing grades with the exception that P grade tubing has a tensile strength of 105,000 psi and is referred to as P105.

Tubing comes with non-upset (NUE) and external upset (EUE) ends. EUE tubing is more common, because of the benefit that cutting threads into the tubing ends does not reduce the body strength.

NB: for ESP applications, if power cable clearance between the tubing and casing becomes an issue, NUE tubing should be considered.

Internal diameter (ID): is a result of the OD and the wall thickness, and it is used to calculate pressure losses and velocities.

The drift diameter: is the diameter of a 42” long mandrel that passes through tubing joint. It is a foremost parameter as it gives the maximum OD of any equipment to run through the tubing string.

Maximum outside diameter: it depends on the nominal diameter and the connection type. It is critical as it determines the strings size that we can run in a given casing.

Nominal size: is the outside diameter of the pipe body. The most used sizes are: 2-⅜”, 2-⅞”, 3-½” and 4-½”.

The tubing joint length: is the length of tubing joint including the coupling and excluding the pin thread. It is classified into two length range: range I: from 20 ft to 24 ft (6.1 to 7.32 m) long, or range II: from 28 ft to 32 ft (8.53 to 9.75 m) long. The length range must be chosen with care. It must be compatible with the hoisting and storage capacity of the mast of the rig used when running in hole the equipment during completion as well as later on during workover operations.

What is API tubing

API tubing is used to transport crude oil or natural gas from the layer of the oil and natural gas to surface. It has better pressure during oil or gas production and smaller diameters. When the tubing runs into a well to serve as a conduit for the oil and gas. It can withstand the pressure when the energy extraction process. Tubing can adequately resist loads and deformations associated with production and workovers. The manufacturing process same as casing. But it has added a manufacturing process to thicken the tubing.

Tubing is specified by grade, outer diameter, weight, and connection. API tubing grades correspond to casing grades with the exception that P grade tubing has a tensile strength of 105,000 psi and is referred to as P105.

Tubing comes with non-upset (NUE) and external upset (EUE) ends. EUE tubing is more common, because of the benefit that cutting threads into the tubing ends does not reduce the body strength.

NB: for ESP applications, if power cable clearance between the tubing and casing becomes an issue, NUE tubing should be considered.

Internal diameter (ID): is a result of the OD and the wall thickness, and it is used to calculate pressure losses and velocities.

The drift diameter: is the diameter of a 42” long mandrel that passes through tubing joint. It is a foremost parameter as it gives the maximum OD of any equipment to run through the tubing string.

Maximum outside diameter: it depends on the nominal diameter and the connection type. It is critical as it determines the strings size that we can run in a given casing.

Nominal size: is the outside diameter of the pipe body. The most used sizes are: 2-⅜”, 2-⅞”, 3-½” and 4-½”.

The tubing joint length: is the length of tubing joint including the coupling and excluding the pin thread. It is classified into two length range: range I: from 20 ft to 24 ft (6.1 to 7.32 m) long, or range II: from 28 ft to 32 ft (8.53 to 9.75 m) long. The length range must be chosen with care. It must be compatible with the hoisting and storage capacity of the mast of the rig used when running in hole the equipment during completion as well as later on during workover operations.

Size of API tubing

Size of API tubing

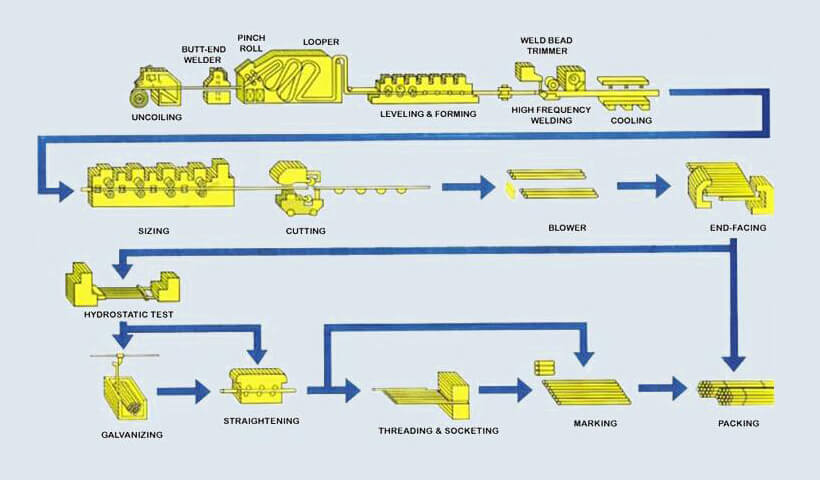

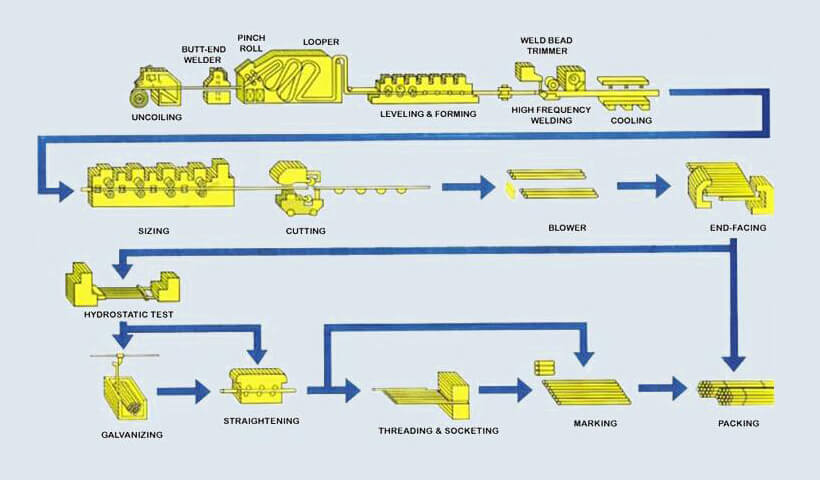

Manufacturing process of API tubing

Manufacturing process of API tubing

Standard of API tubing

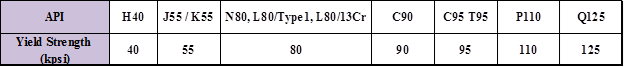

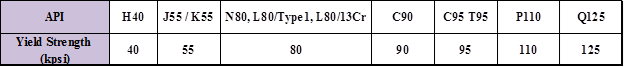

API standard steels and grades for tubing: J55, C75, L80, N80, C90, and P105. The letter is a characteristic of the chemical composition and sometimes the thermal treatment. The number following the letter is the minimum body yield stress in 1000 psi. And it is the minimum body yield stress guaranteed by the manufacturer.

API standard as per API tubing:

Standard of API tubing

API standard steels and grades for tubing: J55, C75, L80, N80, C90, and P105. The letter is a characteristic of the chemical composition and sometimes the thermal treatment. The number following the letter is the minimum body yield stress in 1000 psi. And it is the minimum body yield stress guaranteed by the manufacturer.

API standard as per API tubing:

Application of API tubing

Extracting Oil or Gas from Wells

Application of API tubing

Extracting Oil or Gas from Wells

About Us / News / Product / Project / Quality Assurance / Service / Contact Us