| Availability: | |

|---|---|

What is the straight seam welded pipe

The straight seam welded pipe is mainly divided into ERW steel pipe and LSAW steel pipe. And the welding methods are different: high-frequency welding, arc welding, etc.

ERW steel pipe

High-frequency welded pipes are generally straight-slit, but straight-slit welded steel pipes are not necessarily high-frequency welded. The high-frequency straight-slit electric resistance welded steel pipe is formed by the skin effect and the proximity effect of the high-frequency current after the hot-rolled coil plate is formed by the molding machine, and the edge of the tube blank is heated and melted, and pressure welding is performed under the action of the pressing roller to realize the production. The high-frequency resistance welded steel pipe is different from the ordinary welded pipe welding process. The weld is made of the base material of the steel strip body, and the mechanical strength is better than that of the general welded pipe. The surface is smooth, high precision, low cost, and has low weld seam height, which is beneficial to the coating of 3PE anti-corrosion coating.

LSAW steel pipe

Longitudinal submerged arc welded is produced by using a single medium and thick plate as the raw material, pressing (rolling) the steel plate in a mold or forming machine into a tube blank, using double-sided submerged arc welding, and expanding the diameter. The steel plate feed amount can be automatically adjusted according to different steel grades, wall thicknesses, and plate widths. At the same time, the deformation compensation function effectively avoids the adverse effects of mold deformation on the forming and ensures the flatness of the full length of the steel plate during the pressing process. The feeding step is uniform during forming, ensuring the roundness of the tube blank and the flatness of the welding edge. The finished product has a wide range of specifications, and the weld has good toughness, plasticity, uniformity, and compactness. It has the advantages of large pipe diameter, pipe wall thickness, high-pressure resistance, low-temperature resistance, and strong corrosion resistance.

What is the straight seam welded pipe

The straight seam welded pipe is mainly divided into ERW steel pipe and LSAW steel pipe. And the welding methods are different: high-frequency welding, arc welding, etc.

ERW steel pipe

High-frequency welded pipes are generally straight-slit, but straight-slit welded steel pipes are not necessarily high-frequency welded. The high-frequency straight-slit electric resistance welded steel pipe is formed by the skin effect and the proximity effect of the high-frequency current after the hot-rolled coil plate is formed by the molding machine, and the edge of the tube blank is heated and melted, and pressure welding is performed under the action of the pressing roller to realize the production. The high-frequency resistance welded steel pipe is different from the ordinary welded pipe welding process. The weld is made of the base material of the steel strip body, and the mechanical strength is better than that of the general welded pipe. The surface is smooth, high precision, low cost, and has low weld seam height, which is beneficial to the coating of 3PE anti-corrosion coating.

LSAW steel pipe

Longitudinal submerged arc welded is produced by using a single medium and thick plate as the raw material, pressing (rolling) the steel plate in a mold or forming machine into a tube blank, using double-sided submerged arc welding, and expanding the diameter. The steel plate feed amount can be automatically adjusted according to different steel grades, wall thicknesses, and plate widths. At the same time, the deformation compensation function effectively avoids the adverse effects of mold deformation on the forming and ensures the flatness of the full length of the steel plate during the pressing process. The feeding step is uniform during forming, ensuring the roundness of the tube blank and the flatness of the welding edge. The finished product has a wide range of specifications, and the weld has good toughness, plasticity, uniformity, and compactness. It has the advantages of large pipe diameter, pipe wall thickness, high-pressure resistance, low-temperature resistance, and strong corrosion resistance.

Size chart of straight seam welded pipe

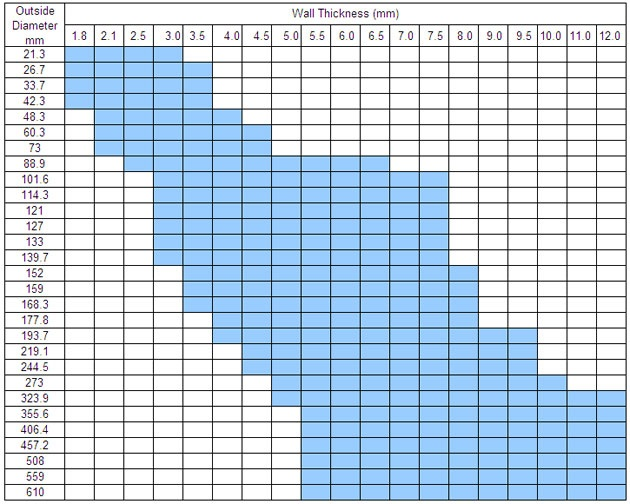

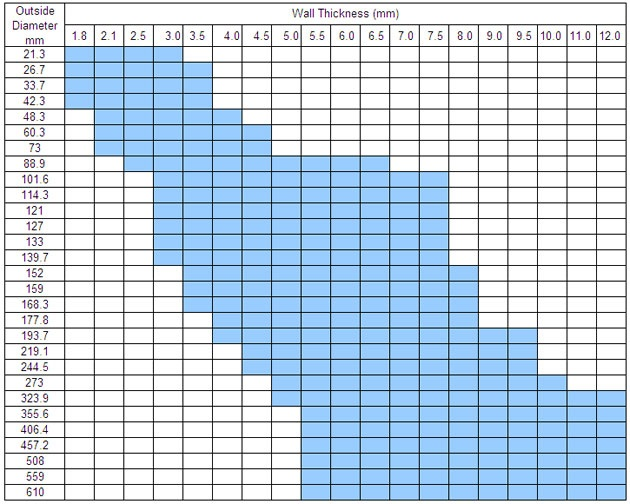

ERW steel pipe size chart

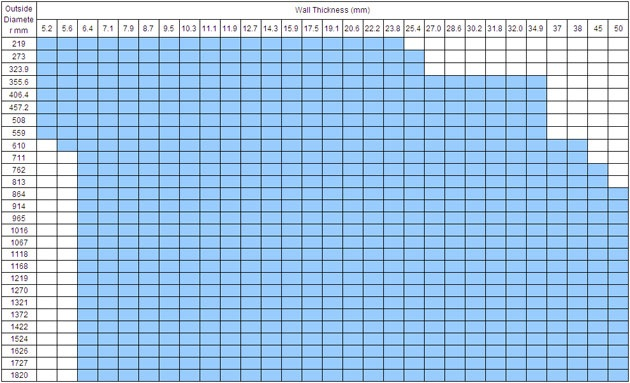

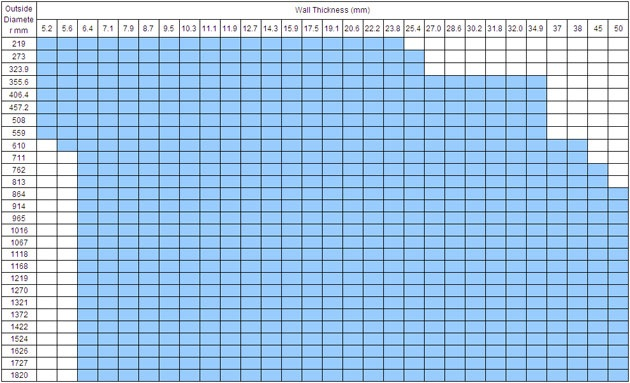

LSAW steel pipe size chart

Size chart of straight seam welded pipe

ERW steel pipe size chart

LSAW steel pipe size chart

The manufacturing process of straight seam welded pipe

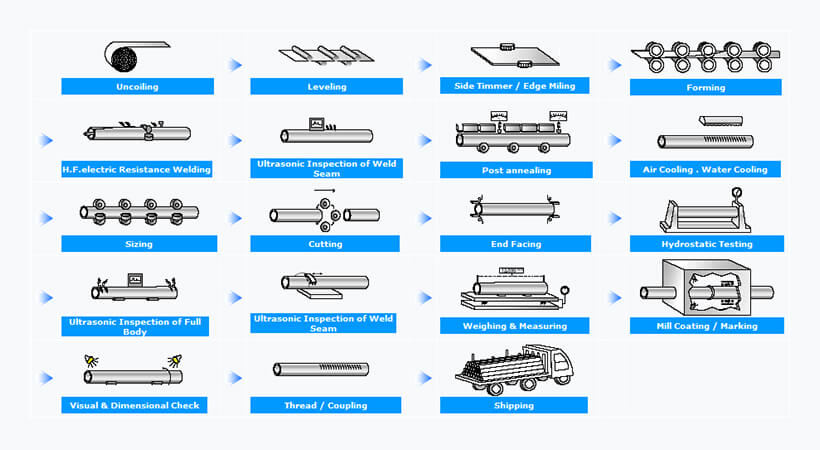

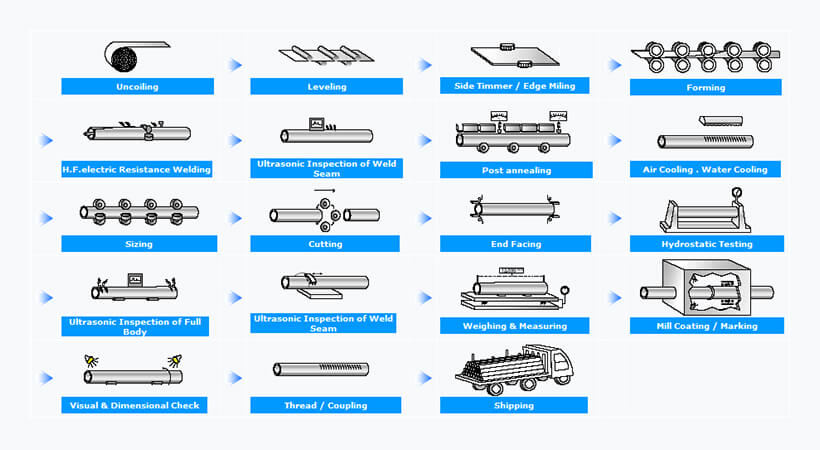

ERW steel pipe manufacturing process

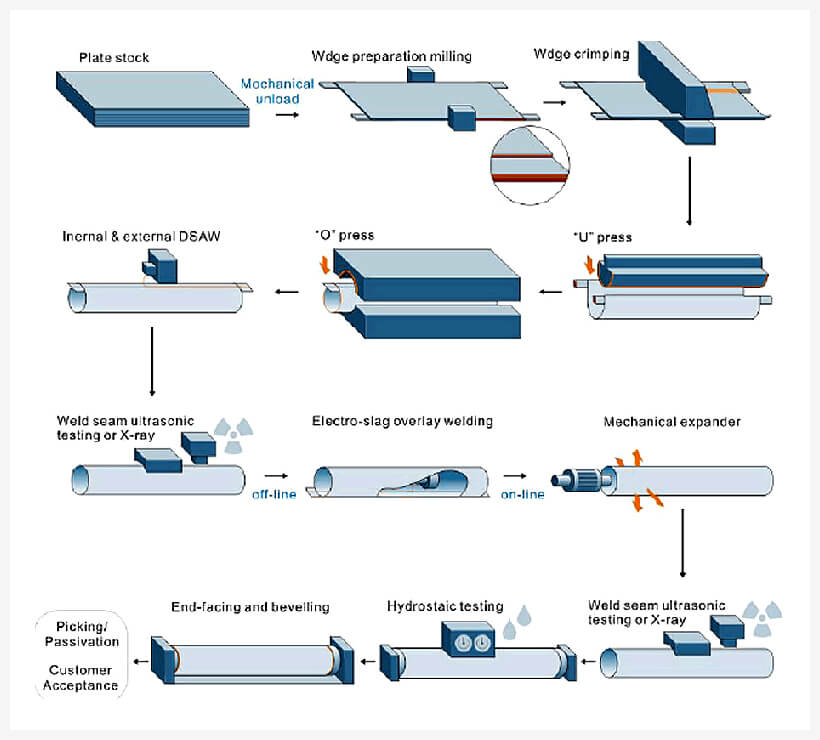

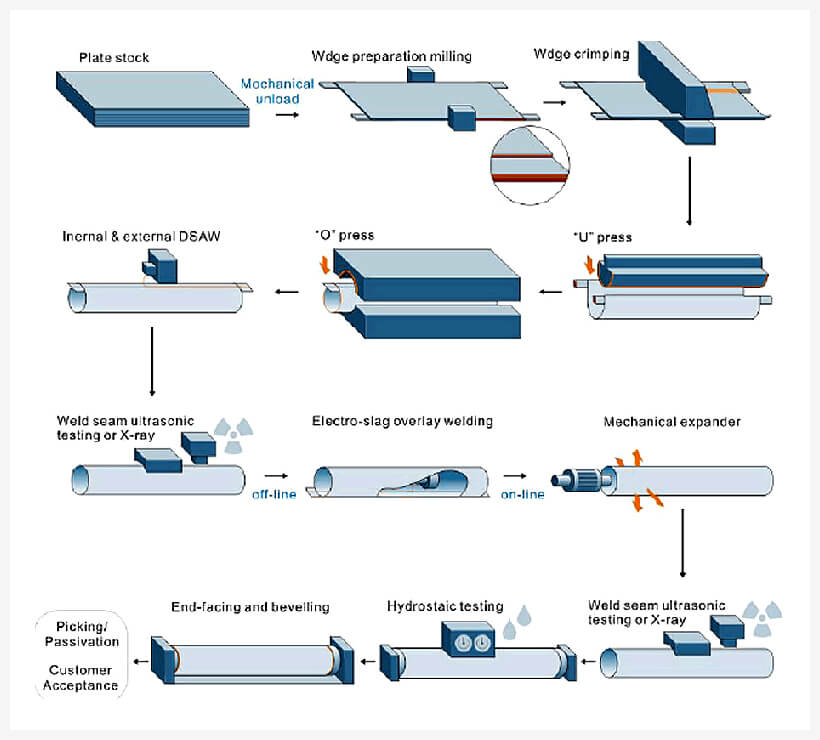

LSAW steel pipe manufacturing process

The manufacturing process of straight seam welded pipe

ERW steel pipe manufacturing process

LSAW steel pipe manufacturing process

Standard of straight seam welded pipe

LSAW steel pipe

API 5L, API 5CT, ASTM 53, EN10217, DIN 2458. IS 3589, GB/T3091, GB/T9711

ERW steel pipe

API 5L, API 5CT, ASTM 53, EN10217, DIN 2458. IS 3589, JIS G3452, BS1387

Standard of straight seam welded pipe

LSAW steel pipe

API 5L, API 5CT, ASTM 53, EN10217, DIN 2458. IS 3589, GB/T3091, GB/T9711

ERW steel pipe

API 5L, API 5CT, ASTM 53, EN10217, DIN 2458. IS 3589, JIS G3452, BS1387

Application of straight seam welded pipe

Fluid service

Low-pressure fluid service

Pipelines for low-pressure fluid service

Pressure purposes

Pipe piles

Cold-formed welded structural hollow sections of non-alloy and fine grain steels

The pipeline transportation system of petroleum and natural gas industries(Class A steel pipe)

Using as casing or tubing for wells of petroleum and natural gas industries

Application of straight seam welded pipe

Fluid service

Low-pressure fluid service

Pipelines for low-pressure fluid service

Pressure purposes

Pipe piles

Cold-formed welded structural hollow sections of non-alloy and fine grain steels

The pipeline transportation system of petroleum and natural gas industries(Class A steel pipe)

Using as casing or tubing for wells of petroleum and natural gas industries

About Us / News / Product / Project / Quality Assurance / Service / Contact Us