| Availability: | |

|---|---|

What is the Spiral Welded Pipe

Spiral welded pipe(SSAW pipe, also called HSAW pipe). The pipe is formed by spiral submerged arc welding technology. Spiral welded pipes are formed using narrower plates or hot rolled coils, which lowers their production costs significantly. The welding line shape like a helix. The spiral welding process permits the production of large-diameter pipes suitable for transporting large volumes of oil and gas. Some SSAW pipes were historically limited to low-pressure applications.

Spiral-welded pipe is manufactured from coils of steel that are unwound and flattened. The flattened strip is formed by right-angle rollers into a cylinder of the desired diameter.

The weld is welded under powder coating. This process is also known as Submerged Arc Welding (SAW). At the end of the spiral, a new spiral is welded to the back edge of the pipe, creating a cross seam. The pipe is cut to length and the ends are beveled if necessary.

Spiral pipe manufacturing has come a long way in recent decades. Cold bending of a spiral pipe was very difficult in the past, but thanks to better manufacturing processes, it can be bent even easier than a steel pipe with a straight weld seam.

Spiral pipes also have close tolerances on the outside diameter and are to weld as ordinary steel pipes. Spiral pipes, like ordinary pipes, can be coated and lined without difficulty.

This type of pipe is used in large pipeline systems around the world, and thanks to the spiral structure of the pipe, spiral pipe also has the most favorable properties for stopping a running crack. Because of these advantages, spiral welded pipe is used in a wide range of applications.

What is the Spiral Welded Pipe

Spiral welded pipe(SSAW pipe, also called HSAW pipe). The pipe is formed by spiral submerged arc welding technology. Spiral welded pipes are formed using narrower plates or hot rolled coils, which lowers their production costs significantly. The welding line shape like a helix. The spiral welding process permits the production of large-diameter pipes suitable for transporting large volumes of oil and gas. Some SSAW pipes were historically limited to low-pressure applications.

Spiral-welded pipe is manufactured from coils of steel that are unwound and flattened. The flattened strip is formed by right-angle rollers into a cylinder of the desired diameter.

The weld is welded under powder coating. This process is also known as Submerged Arc Welding (SAW). At the end of the spiral, a new spiral is welded to the back edge of the pipe, creating a cross seam. The pipe is cut to length and the ends are beveled if necessary.

Spiral pipe manufacturing has come a long way in recent decades. Cold bending of a spiral pipe was very difficult in the past, but thanks to better manufacturing processes, it can be bent even easier than a steel pipe with a straight weld seam.

Spiral pipes also have close tolerances on the outside diameter and are to weld as ordinary steel pipes. Spiral pipes, like ordinary pipes, can be coated and lined without difficulty.

This type of pipe is used in large pipeline systems around the world, and thanks to the spiral structure of the pipe, spiral pipe also has the most favorable properties for stopping a running crack. Because of these advantages, spiral welded pipe is used in a wide range of applications.

Size chart of Spiral Welded Pipe

Outer Diameter | Wall Thickness (mm) | |||||||||||||||||||

6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | |

219.1 | . | . | . | . | ||||||||||||||||

273 | . | . | . | . | . | |||||||||||||||

323.9 | . | . | . | . | . | . | . | |||||||||||||

325 | . | . | . | . | . | . | . | |||||||||||||

355.6 | . | . | . | . | . | . | . | |||||||||||||

377 | . | . | . | . | . | . | . | . | ||||||||||||

406.4 | . | . | . | . | . | . | . | |||||||||||||

426 | . | . | . | . | . | . | . | |||||||||||||

457 | . | . | . | . | . | . | . | |||||||||||||

478 | . | . | . | . | . | . | . | |||||||||||||

508 | . | . | . | . | . | . | . | . | ||||||||||||

529 | . | . | . | . | . | . | . | . | ||||||||||||

630 | . | . | . | . | . | . | . | . | . | |||||||||||

711 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

720 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

813 | . | . | . | . | . | . | . | . | . | . | . | . | ||||||||

820 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

920 | . | . | . | . | . | . | . | . | . | . | ||||||||||

1020 | . | . | . | . | . | . | . | . | . | . | . | . | . | |||||||

1220 | . | . | . | . | . | . | . | . | . | . | . | . | . | |||||||

1420 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

1620 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

1820 | . | . | . | . | . | . | . | . | . | . | ||||||||||

2020 | . | . | . | . | . | . | . | . | . | |||||||||||

2220 | . | . | . | . | . | . | . | . | ||||||||||||

2500 | . | . | . | . | . | . | . | . | . | . | . | . | . | |||||||

2540 | . | . | . | . | . | . | . | . | . | . | . | . | ||||||||

3500 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

Size chart of Spiral Welded Pipe

Outer Diameter | Wall Thickness (mm) | |||||||||||||||||||

6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | |

219.1 | . | . | . | . | ||||||||||||||||

273 | . | . | . | . | . | |||||||||||||||

323.9 | . | . | . | . | . | . | . | |||||||||||||

325 | . | . | . | . | . | . | . | |||||||||||||

355.6 | . | . | . | . | . | . | . | |||||||||||||

377 | . | . | . | . | . | . | . | . | ||||||||||||

406.4 | . | . | . | . | . | . | . | |||||||||||||

426 | . | . | . | . | . | . | . | |||||||||||||

457 | . | . | . | . | . | . | . | |||||||||||||

478 | . | . | . | . | . | . | . | |||||||||||||

508 | . | . | . | . | . | . | . | . | ||||||||||||

529 | . | . | . | . | . | . | . | . | ||||||||||||

630 | . | . | . | . | . | . | . | . | . | |||||||||||

711 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

720 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

813 | . | . | . | . | . | . | . | . | . | . | . | . | ||||||||

820 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

920 | . | . | . | . | . | . | . | . | . | . | ||||||||||

1020 | . | . | . | . | . | . | . | . | . | . | . | . | . | |||||||

1220 | . | . | . | . | . | . | . | . | . | . | . | . | . | |||||||

1420 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

1620 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

1820 | . | . | . | . | . | . | . | . | . | . | ||||||||||

2020 | . | . | . | . | . | . | . | . | . | |||||||||||

2220 | . | . | . | . | . | . | . | . | ||||||||||||

2500 | . | . | . | . | . | . | . | . | . | . | . | . | . | |||||||

2540 | . | . | . | . | . | . | . | . | . | . | . | . | ||||||||

3500 | . | . | . | . | . | . | . | . | . | . | . | |||||||||

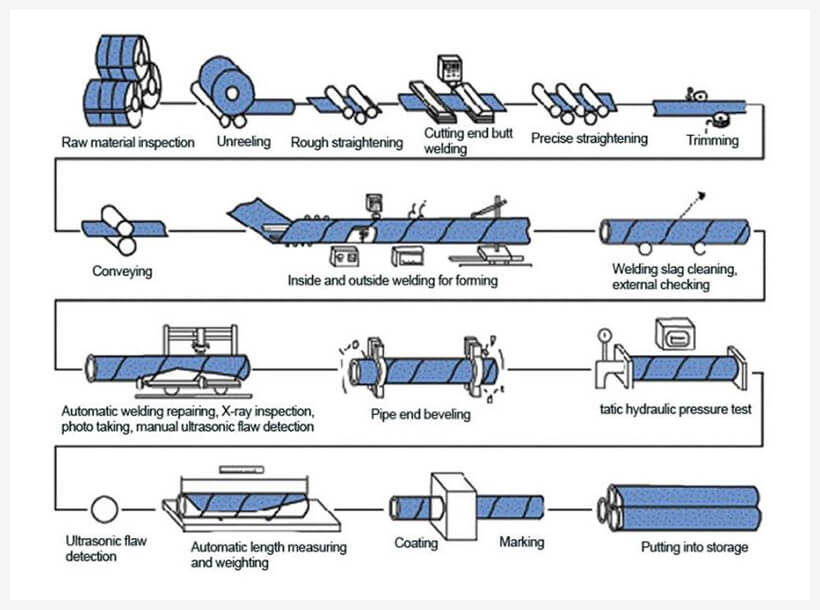

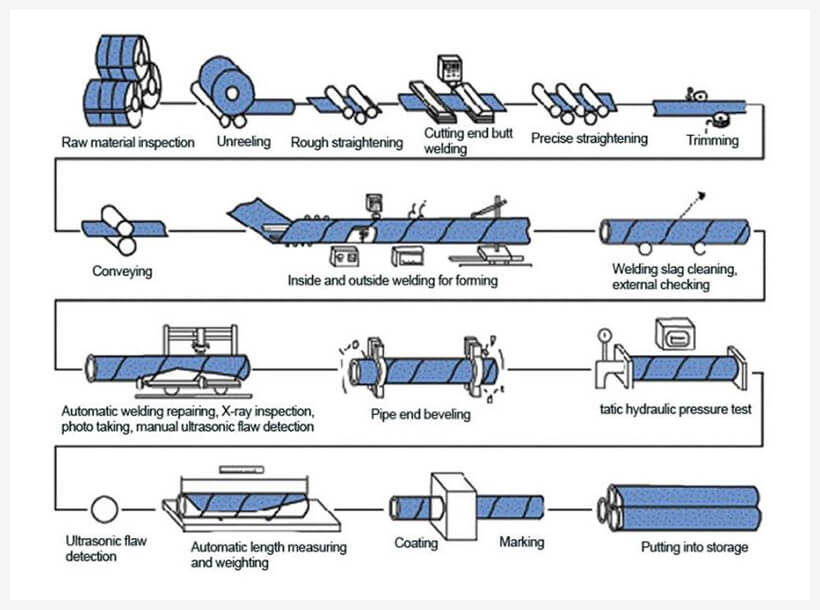

The manufacturing process of spiral welded pipe

The manufacturing process of spiral welded pipe

Standard of spiral welded pipe

Steel Pipe for Fluid Service | GB/T 14291 | Welded pipe for mine fluid service |

GB/T 3091 | Welded pipe for low-pressure fluid service | |

SY/T 5037 | Spirally submerged arc welded steel pipe for pipelines for low-pressure fluid service | |

ASTM A53 | Black and hot-dipped galvanized welded and seamless steel pipe | |

BS EN10217-2 | Welded steel tubes for pressure purposes - delivery technical conditions - part2: Electric welded non- alloy and alloy steel tubes with specified elevated temperature properties | |

BS EN10217-5 | Welded steel tubes for pressure purposes - delivery technical conditions - part5: submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties | |

Steel Pipe for Ordinary Structure | GB/T 13793 | Longitudinally electric resistance welded steel pipe |

SY/T 5040 | Spirally submerged arc welded steel pipe piles | |

ASTM A252 | Welded and seamless steel pipe piles | |

BS EN10219-1 | Cold-formed welded structural hollow sections of non-alloy and fine grain steels - part1: Technical delivery conditions | |

BS EN10219-2 | Cold-formed welded structural hollow sections of non-alloy and fine grain steels - part2: tolerances dimensions and sectional properties | |

Line Pipe | GB/T 9711.1 | Steel pipe for the pipeline transportation system of petroleum and natural gas industries(Class A steel pipe) |

GB/T 9711.2 | Steel pipe for the pipeline transportation system of petroleum and natural gas industries(Class B steel pipe) | |

API 5L PSL1/2 | Line pipe | |

Casing | API 5CT/ ISO 11960 PSL1 | Steel pipe for use as casing or tubing for wells of petroleum and natural gas industries |

Standard of spiral welded pipe

Steel Pipe for Fluid Service | GB/T 14291 | Welded pipe for mine fluid service |

GB/T 3091 | Welded pipe for low-pressure fluid service | |

SY/T 5037 | Spirally submerged arc welded steel pipe for pipelines for low-pressure fluid service | |

ASTM A53 | Black and hot-dipped galvanized welded and seamless steel pipe | |

BS EN10217-2 | Welded steel tubes for pressure purposes - delivery technical conditions - part2: Electric welded non- alloy and alloy steel tubes with specified elevated temperature properties | |

BS EN10217-5 | Welded steel tubes for pressure purposes - delivery technical conditions - part5: submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties | |

Steel Pipe for Ordinary Structure | GB/T 13793 | Longitudinally electric resistance welded steel pipe |

SY/T 5040 | Spirally submerged arc welded steel pipe piles | |

ASTM A252 | Welded and seamless steel pipe piles | |

BS EN10219-1 | Cold-formed welded structural hollow sections of non-alloy and fine grain steels - part1: Technical delivery conditions | |

BS EN10219-2 | Cold-formed welded structural hollow sections of non-alloy and fine grain steels - part2: tolerances dimensions and sectional properties | |

Line Pipe | GB/T 9711.1 | Steel pipe for the pipeline transportation system of petroleum and natural gas industries(Class A steel pipe) |

GB/T 9711.2 | Steel pipe for the pipeline transportation system of petroleum and natural gas industries(Class B steel pipe) | |

API 5L PSL1/2 | Line pipe | |

Casing | API 5CT/ ISO 11960 PSL1 | Steel pipe for use as casing or tubing for wells of petroleum and natural gas industries |

Application of spiral welded pipe

Water supply engineering

Petrochemical industry

Chemical industry

Electric power industry

Agricultural irrigation

Urban construction.

Water supply and drainage.

Gas transport

Structure construction

Application of spiral welded pipe

Water supply engineering

Petrochemical industry

Chemical industry

Electric power industry

Agricultural irrigation

Urban construction.

Water supply and drainage.

Gas transport

Structure construction

About Us / News / Product / Project / Quality Assurance / Service / Contact Us