| Availability: | |

|---|---|

What is EN 10025 pipe

En 10025 Pipes manufacturer produce these carbon steel pipes with carbon, silicon, manganese, phosphorus, and sulfur content. The carbon content is 0.2% of the total weight. The EN 10025 Steel Pipes is made in seamless and welded conditions. The difference between the two is that the welded pipes have larger diameters and high absolute roughness where the En 10025 Seamless Pipes have low absolute roughness and smaller diameters. The seamless pipes are cold drawn or hot rolled from the raw material where the welded pipes are welded from plates to form the BS 10025 Wn 1.0570 Round Pipe. There are square, rectangular, and hydraulic pipe types available as well. The En 10025-3 Square Pipes is used for structural applications where lightweight is preferred. The square shape provides extra strength. The En 10025 ERW Pipes is used in high pressure, high-temperature applications. The material has high corrosion resistance, temperature resistance, wear and tear resistance, and toughness. The preheating or post-weld heat treatment is not necessary to weld the En 10025 Cold Drawn Pipes and it could be welded with most traditional methods.

What is EN 10025 pipe

En 10025 Pipes manufacturer produce these carbon steel pipes with carbon, silicon, manganese, phosphorus, and sulfur content. The carbon content is 0.2% of the total weight. The EN 10025 Steel Pipes is made in seamless and welded conditions. The difference between the two is that the welded pipes have larger diameters and high absolute roughness where the En 10025 Seamless Pipes have low absolute roughness and smaller diameters. The seamless pipes are cold drawn or hot rolled from the raw material where the welded pipes are welded from plates to form the BS 10025 Wn 1.0570 Round Pipe. There are square, rectangular, and hydraulic pipe types available as well. The En 10025-3 Square Pipes is used for structural applications where lightweight is preferred. The square shape provides extra strength. The En 10025 ERW Pipes is used in high pressure, high-temperature applications. The material has high corrosion resistance, temperature resistance, wear and tear resistance, and toughness. The preheating or post-weld heat treatment is not necessary to weld the En 10025 Cold Drawn Pipes and it could be welded with most traditional methods.

Size chart of EN 10025 pipe

En 10025 Hot Rolled Pipe Sizes | |

1/8" IPS(.405" O.D.) | 3 1/2" IPS( 4.000" O.D.) |

SCH 40, 80 | SCH 10, 40, 80, 160, XXH |

1/4" IPS(.540" O.D.) | 4" IPS(4.500" O.D.) |

SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

3/8" IPS(.675" O.D.) | 5" IPS( 5.563" O.D.) |

SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

1/2" IPS(.840" O.D.) | 6" IPS(6.625" O.D.) |

SCH 5, 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

3/4" IPS(1.050" O.D.) | 8 ” IPS(8.625" O.D.) |

SCH 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

1" IPS:(1.315′ O.D.) | 10" IPS(10.750" O.D.) |

SCH 5, 10, 40, 80, 160, XXH | SCH 10, 20, 40, 80 (.500), TRUE 80(.500) |

1-1/4" IPS(1.660" O.D.) | 12" IPS(12.750" O.D.) |

SCH 10, 40, 80, 160, XXH | SCH 10, 20, 40(.375), TRUE40(.406), SCH80(.500) |

1-1/2" IPS(1.900" O.D.) | 14" IPS(14.000" O.D.) |

SCH 10, 40, 80, 160, XXH | SCH10 (.188), SCH40 (.375) |

2" IPS(2.375" O.D.) | 16" IPS(16.000" O.D.) |

SCH 10, 40, 80, 160, XXH | SCH10(.188), SCH40(.375) |

2 1/2" IPS(2.875" O.D.) | 18" IPS (18.000" O.D.) |

SCH 10, 40, 80, 160, XXH | SCH-40 (.375) |

3" IPS( 3.500" O.D.) | |

SCH 5, 10, 40, 80, 160, XXH | |

En 10025 Mild Steel Tube Sizes | |

Wall | Sizes ( O.D.) |

0.01 | 1/16" , 1/8" , 3/16" |

0.02 | 1/16" , 1/8" , 3/16" , 1/4" , 5/16" , 3/8" |

0.012 | 1/8" |

0.016 | 1/8" , 3/16" |

0.028 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 3/4" , 1" , 1 1/2" , 2" |

0.035 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 7/16" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

0.049 | 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/8" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

0.065 | 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 3/4" , 2" , 2 1/2" , 3" |

0.083 | 1/4" , 3/8" , 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 7/8" , 2" , 2 1/2" ,3" |

0.095 | 1/2" , 5/8" , 1" , 1 1/4" , 1 1/2" , 2" |

0.109 | 1/2" , 3/4" , 1" , 1 1/4" , 1 1/2" , 2" |

0.12 | 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 2" , 2 1/4" , 2 1/2" , 3" |

0.125 | 3/4" , 1" , 1 1/4" , 1 1/2" , 2" , 3" , 3 1/4" |

0.134 | 1" |

0.25 | 3" |

0.375 | 3 1/2" |

Size chart of EN 10025 pipe

En 10025 Hot Rolled Pipe Sizes | |

1/8" IPS(.405" O.D.) | 3 1/2" IPS( 4.000" O.D.) |

SCH 40, 80 | SCH 10, 40, 80, 160, XXH |

1/4" IPS(.540" O.D.) | 4" IPS(4.500" O.D.) |

SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

3/8" IPS(.675" O.D.) | 5" IPS( 5.563" O.D.) |

SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

1/2" IPS(.840" O.D.) | 6" IPS(6.625" O.D.) |

SCH 5, 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

3/4" IPS(1.050" O.D.) | 8 ” IPS(8.625" O.D.) |

SCH 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

1" IPS:(1.315′ O.D.) | 10" IPS(10.750" O.D.) |

SCH 5, 10, 40, 80, 160, XXH | SCH 10, 20, 40, 80 (.500), TRUE 80(.500) |

1-1/4" IPS(1.660" O.D.) | 12" IPS(12.750" O.D.) |

SCH 10, 40, 80, 160, XXH | SCH 10, 20, 40(.375), TRUE40(.406), SCH80(.500) |

1-1/2" IPS(1.900" O.D.) | 14" IPS(14.000" O.D.) |

SCH 10, 40, 80, 160, XXH | SCH10 (.188), SCH40 (.375) |

2" IPS(2.375" O.D.) | 16" IPS(16.000" O.D.) |

SCH 10, 40, 80, 160, XXH | SCH10(.188), SCH40(.375) |

2 1/2" IPS(2.875" O.D.) | 18" IPS (18.000" O.D.) |

SCH 10, 40, 80, 160, XXH | SCH-40 (.375) |

3" IPS( 3.500" O.D.) | |

SCH 5, 10, 40, 80, 160, XXH | |

En 10025 Mild Steel Tube Sizes | |

Wall | Sizes ( O.D.) |

0.01 | 1/16" , 1/8" , 3/16" |

0.02 | 1/16" , 1/8" , 3/16" , 1/4" , 5/16" , 3/8" |

0.012 | 1/8" |

0.016 | 1/8" , 3/16" |

0.028 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 3/4" , 1" , 1 1/2" , 2" |

0.035 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 7/16" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

0.049 | 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/8" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

0.065 | 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 3/4" , 2" , 2 1/2" , 3" |

0.083 | 1/4" , 3/8" , 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 7/8" , 2" , 2 1/2" ,3" |

0.095 | 1/2" , 5/8" , 1" , 1 1/4" , 1 1/2" , 2" |

0.109 | 1/2" , 3/4" , 1" , 1 1/4" , 1 1/2" , 2" |

0.12 | 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 2" , 2 1/4" , 2 1/2" , 3" |

0.125 | 3/4" , 1" , 1 1/4" , 1 1/2" , 2" , 3" , 3 1/4" |

0.134 | 1" |

0.25 | 3" |

0.375 | 3 1/2" |

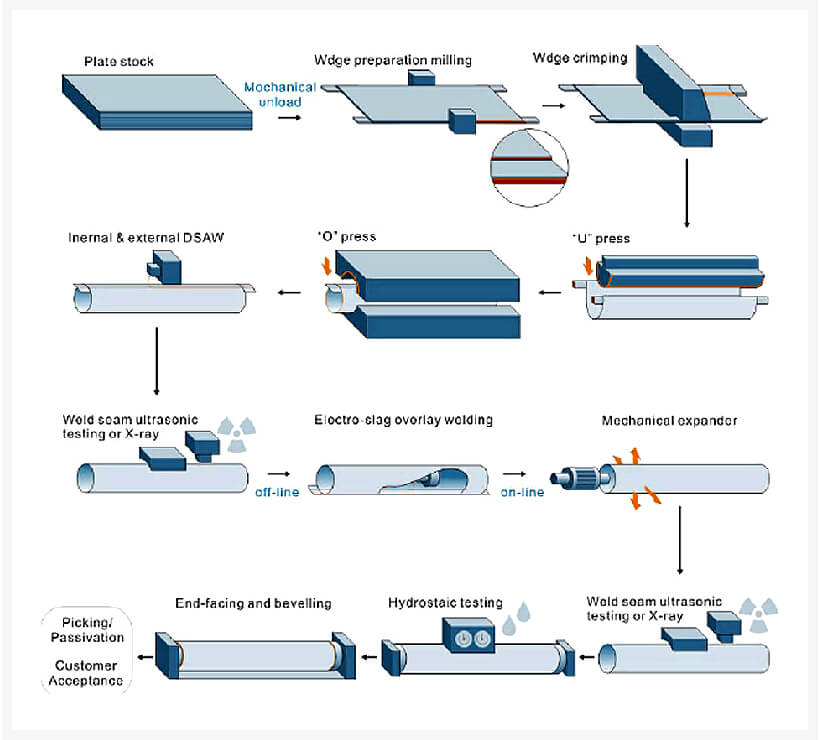

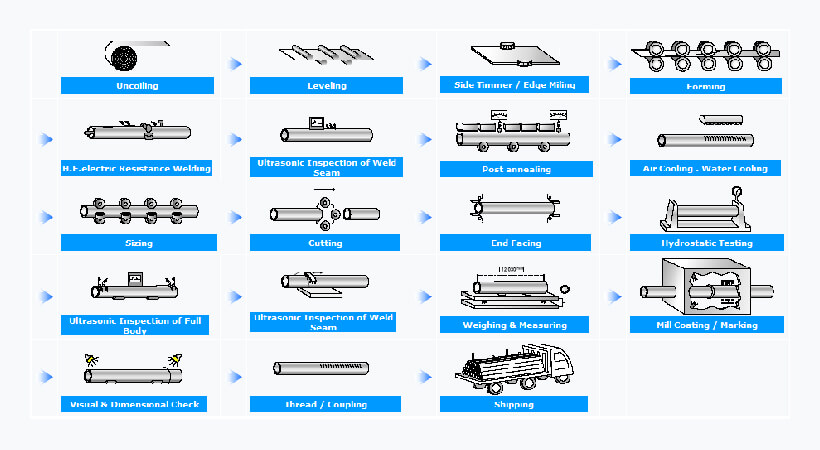

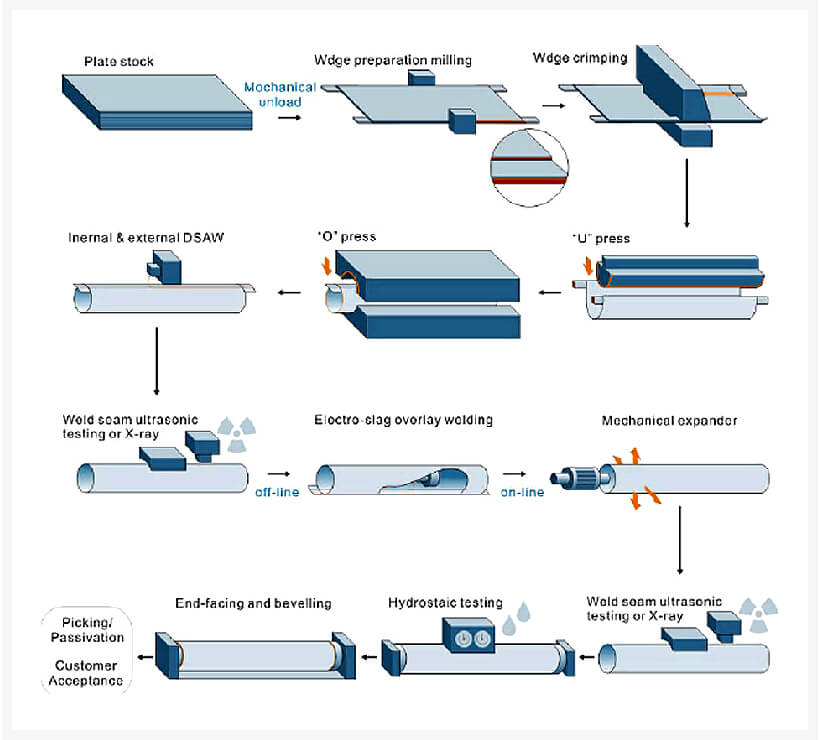

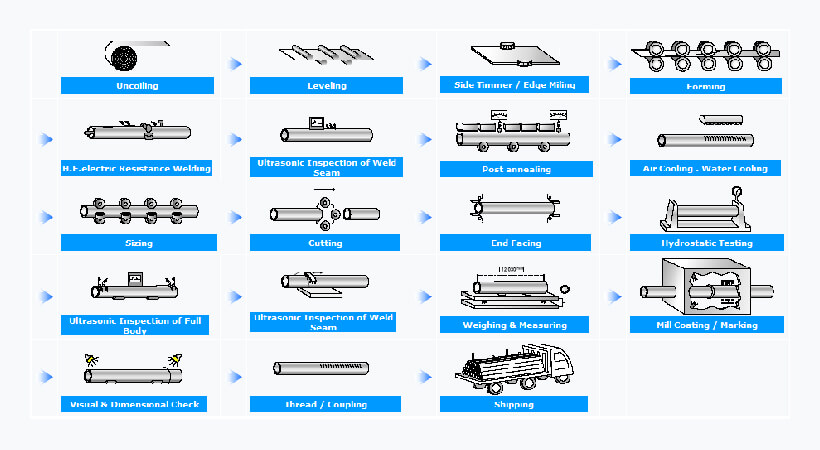

Manufacturing process of EN 10025 pipe

Manufacturing process of EN 10025 pipe

Standard of EN 10025 pipe

En 10025-2 Chemical Composition | |||||||||

Carbon | Silicon | Manganese | Phosphorous | Sulphur | Molybdenum | Nickel | Chromium | Copper | Others |

max 0.20 | max 0.55 | max 1.60 | 0.035 | 0.035 | – | – | – | – | – |

En 10025 Steel Mechanical Properties | |||||||||

Yield Strength | Tensile Strength | Elongation A5 min | |||||||

MPa min | ksi min | MPa min | MPa min | ksi min | Percentage | ||||

490 | 630 | – | – | ||||||

Standard of EN 10025 pipe

En 10025-2 Chemical Composition | |||||||||

Carbon | Silicon | Manganese | Phosphorous | Sulphur | Molybdenum | Nickel | Chromium | Copper | Others |

max 0.20 | max 0.55 | max 1.60 | 0.035 | 0.035 | – | – | – | – | – |

En 10025 Steel Mechanical Properties | |||||||||

Yield Strength | Tensile Strength | Elongation A5 min | |||||||

MPa min | ksi min | MPa min | MPa min | ksi min | Percentage | ||||

490 | 630 | – | – | ||||||

Application of EN 10025 pipe

Vehicle structure

Building construction

Bridges construction

Ship building

Application of EN 10025 pipe

Vehicle structure

Building construction

Bridges construction

Ship building

About Us / News / Product / Project / Quality Assurance / Service / Contact Us