| Availability: | |

|---|---|

What is API casing

There are seamless and welded steel pipes established the API casing. It's an important part of the oil drilling process. It is produced according to the API 5CT standard. It is most often used in underground construction projects to encase or protect utility lines from being damaged. It is widely used in cement projects to serve as the structural retainer for the wall of oil and gas wells or wellbore. API casing is an integral part of the oil drilling and completion process. API casing with a good structure and strength to the walls of the good hole so that it doesn't collapse on itself. It ensures that there is no seepage of oil or natural gas is out of the good hole as these are brought to the surface. It is inserted into a wellbore and cemented to protect both subsurface formations and the wellbore from collapsing and allow drilling fluid to circulate and extract.

Casing is a large-diameter pipe that serves as the structural retainer for the walls of oil and gas wells, or well bore.It is inserted into a well bore and cemented in place to protect both subsurface formations and the well bore from collapsing and to allow drilling fluid to circulate and extraction to take place. Steel Casing Pipes have smooth wall & minimum yield strength of 35,000 psi.

Well Casing serves as well sidewall. Standards and Technical Conditions for Supply:API Spec 5CT ISO13680 Grade: J55, K55, N80-1,N80-Q, L80-1, L80-9Cr,L80-13Cr,C95, P110. Tread types: NUE, EUE, VAM, STC, LTC, BTC, special clearance, XC,VAM TOP,NEW VAM.

Oil Casing Pipe: Casings are used for fixing the well wall or down hole, which have wide diameters, can be divided into conductor casings, technical casings and Oil casings.

Uses: Well Casing serves as well sidewall.

Standards and Technical Conditions for Supply: API Spec 5CT

Grade of pipe casing: J55, K55, N80-1,N80-Q, L80-1, L80-9Cr,L80-13Cr,C95, P110.

Tread types of pipe casing : STC, LTC, BTC, special clearance, XC,VAM TOP,NEW VAM.

Dimension: OD: 114.3-508mm WT: 5.21-16.13mm

What is API casing

There are seamless and welded steel pipes established the API casing. It's an important part of the oil drilling process. It is produced according to the API 5CT standard. It is most often used in underground construction projects to encase or protect utility lines from being damaged. It is widely used in cement projects to serve as the structural retainer for the wall of oil and gas wells or wellbore. API casing is an integral part of the oil drilling and completion process. API casing with a good structure and strength to the walls of the good hole so that it doesn't collapse on itself. It ensures that there is no seepage of oil or natural gas is out of the good hole as these are brought to the surface. It is inserted into a wellbore and cemented to protect both subsurface formations and the wellbore from collapsing and allow drilling fluid to circulate and extract.

Casing is a large-diameter pipe that serves as the structural retainer for the walls of oil and gas wells, or well bore.It is inserted into a well bore and cemented in place to protect both subsurface formations and the well bore from collapsing and to allow drilling fluid to circulate and extraction to take place. Steel Casing Pipes have smooth wall & minimum yield strength of 35,000 psi.

Well Casing serves as well sidewall. Standards and Technical Conditions for Supply:API Spec 5CT ISO13680 Grade: J55, K55, N80-1,N80-Q, L80-1, L80-9Cr,L80-13Cr,C95, P110. Tread types: NUE, EUE, VAM, STC, LTC, BTC, special clearance, XC,VAM TOP,NEW VAM.

Oil Casing Pipe: Casings are used for fixing the well wall or down hole, which have wide diameters, can be divided into conductor casings, technical casings and Oil casings.

Uses: Well Casing serves as well sidewall.

Standards and Technical Conditions for Supply: API Spec 5CT

Grade of pipe casing: J55, K55, N80-1,N80-Q, L80-1, L80-9Cr,L80-13Cr,C95, P110.

Tread types of pipe casing : STC, LTC, BTC, special clearance, XC,VAM TOP,NEW VAM.

Dimension: OD: 114.3-508mm WT: 5.21-16.13mm

Size of API casing

API casing length

API Casing Length: | |||

API 5CT Casing | Range 1 | Range 2 | Range 3 |

4.88~7.62 | 7.62~10.36 | 10.36~14.63 | |

API Casing Dimension: | |||||||||

Labels | OD(mm) | WT(mm) | J55/K55 | N80 | L80 | C90/T95 | P110 | Q125 | |

4 1/2 | 9.5 | 114.3 | 5.21 | PS | - | - | - | - | - |

10.5 | 114.3 | 5.69 | PSB | - | - | - | - | - | |

11.6 | 114.3 | 6.36 | PSLB | PLB | PLB | PLB | PLB | - | |

13.5 | 114.3 | 7.37 | - | PLB | PLB | PLB | PLB | - | |

15.1 | 114.3 | 8.56 | - | - | - | - | PLB | PLB | |

5 | 11.5 | 127 | 5.59 | PS | - | - | - | - | - |

13 | 6.43 | PSLB | - | - | - | - | - | ||

15 | 7.52 | PSLBE | PLBE | PLBE | PLBE | PLBE | - | ||

18 | 9.19 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

21.4 | 11.1 | - | PLB | PLB | PLB | PLB | PLB | ||

23.2 | 12.14 | - | PLB | PLB | PLB | PLB | PLB | ||

24.1 | 12.7 | - | PLB | PLB | PLB | PLB | PLB | ||

5 1/2 | 14 | 139.7 | 6.2 | PS | - | - | - | - | - |

15.5 | 6.98 | PSLBE | - | - | - | - | - | ||

17 | 7.72 | PSLBE | PLBE | PLBE | PLBE | PLBE | - | ||

20 | 9.17 | - | PLBE | PLBE | PLBE | PLBE | - | ||

23 | 10.54 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

26.8 | 12.7 | - | - | - | P | - | - | ||

29.7 | 14.27 | - | - | - | P | - | - | ||

32.6 | 15.88 | - | - | - | P | - | - | ||

35.3 | 17.45 | - | - | - | P | - | - | ||

38 | 19.05 | - | - | - | P | - | - | ||

40.5 | 20.62 | - | - | - | P | - | - | ||

43.1 | 64.14 | - | - | - | P | - | - | ||

6 5/8 | 20 | 168.28 | 7.32 | PSLB | |||||

24 | 8.94 | PSLBE | PLBE | PLBE | PLBE | PLBE | - | ||

28 | 10.59 | - | PLBE | PLBE | PLBE | PLBE | - | ||

32 | 12.06 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

7 | 20 | 177.8 | 6.91 | PS | |||||

23 | 8.05 | PSLBE | PLBE | PLBE | PLBE | - | - | ||

26 | 9.19 | PSLBE | PLBE | PLBE | PLBE | PLBE | - | ||

29 | 10.6 | PLBE | PLBE | PLBE | PLBE | ||||

32 | 11.51 | PLBE | PLBE | PLBE | PLBE | ||||

35 | 12.65 | PLBE | PLBE | PLBE | PLBE | PLBE | |||

38 | 13.72 | PLBE | PLBE | PLBE | PLBE | PLBE | |||

7 5/8 | 26.4 | 193.67 | 8.33 | PSLBE | PLBE | PLBE | PLBE | - | - |

29.7 | 9.52 | - | PLBE | PLBE | PLBE | PLBE | - | ||

33.7 | 10.92 | - | PLBE | PLBE | PLBE | PLBE | - | ||

39 | 12.7 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

42.8 | 14.27 | - | PLB | PLB | PLB | PLB | PLB | ||

45.3 | 15.11 | - | PLB | PLB | PLB | PLB | PLB | ||

47.1 | 15.88 | - | PLB | PLB | PLB | PLB | PLB | ||

8 5/8 | 24 | 219.08 | 6.71 | PS | - | - | - | - | - |

28 | 7.72 | - | - | - | - | - | - | ||

32 | 8.94 | PSLBE | - | - | - | - | - | ||

36 | 10.16 | PSLBE | PLBE | PLBE | PLBE | - | - | ||

40 | 11.43 | - | PLBE | PLBE | PLBE | PLBE | - | ||

44 | 12.7 | - | PLBE | PLBE | PLBE | PLBE | - | ||

49 | 14.15 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

9 5/8 | 36 | 244.48 | 8.94 | PSLB | - | - | - | - | - |

40 | 10.03 | PSLBE | PLBE | PLBE | PLBE | - | - | ||

43.5 | 11.05 | - | PLBE | PLBE | PLBE | PLBE | |||

47 | 11.99 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

53.5 | 13.84 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

58.4 | 15.11 | - | PLB | PLB | PLB | PLB | PLB | ||

10 3/4 | 40.5 | 273.05 | 8.89 | PSB | - | - | - | - | - |

45.5 | 10.16 | PSBE | - | - | - | - | - | ||

51 | 11.43 | PSBE | PSBE | PSBE | PSBE | PSBE | - | ||

55 | 12.57 | - | PSBE | PSBE | PSBE | PSBE | - | ||

60.7 | 13.84 | - | - | - | PSBE | PSBE | PSBE | ||

65.7 | 15.11 | - | - | - | PSB | PSB | PSB | ||

113/4 | 47 | 298.45 | 9.53 | PSB | - | - | - | - | - |

54 | 11.05 | PSB | - | - | - | - | - | ||

60 | 12.42 | PSB | PSB | PSB | PSB | PSB | PSB | ||

13 3/8 | 48 | 339.72 | 8.38 | - | - | - | - | - | - |

54.5 | 9.65 | PSB | - | - | - | - | - | ||

61 | 10.92 | PSB | - | - | - | - | |||

68 | 12.19 | PSB | PSB | PSB | PSB | PSB | - | ||

72 | 13.06 | - | PSB | PSB | PSB | PSB | PSB | ||

16 | 75 | 406 | 11.13 | PSB | - | - | - | - | - |

84 | 12.57 | PSB | - | - | - | - | - | ||

109 | 16.66 | P | P | P | - | P | P | ||

20 | 94 | 508 | 11.13 | PSLB | - | - | - | - | - |

30 | 96 | 762 | 16.13 | PSLB | - | - | - | - | - |

P-Plain end; S-Short round thread; L-Long round thread; B-Buttress thread; E-Extreme line; | |||||||||

Size of API casing

API casing length

API Casing Length: | |||

API 5CT Casing | Range 1 | Range 2 | Range 3 |

4.88~7.62 | 7.62~10.36 | 10.36~14.63 | |

API Casing Dimension: | |||||||||

Labels | OD(mm) | WT(mm) | J55/K55 | N80 | L80 | C90/T95 | P110 | Q125 | |

4 1/2 | 9.5 | 114.3 | 5.21 | PS | - | - | - | - | - |

10.5 | 114.3 | 5.69 | PSB | - | - | - | - | - | |

11.6 | 114.3 | 6.36 | PSLB | PLB | PLB | PLB | PLB | - | |

13.5 | 114.3 | 7.37 | - | PLB | PLB | PLB | PLB | - | |

15.1 | 114.3 | 8.56 | - | - | - | - | PLB | PLB | |

5 | 11.5 | 127 | 5.59 | PS | - | - | - | - | - |

13 | 6.43 | PSLB | - | - | - | - | - | ||

15 | 7.52 | PSLBE | PLBE | PLBE | PLBE | PLBE | - | ||

18 | 9.19 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

21.4 | 11.1 | - | PLB | PLB | PLB | PLB | PLB | ||

23.2 | 12.14 | - | PLB | PLB | PLB | PLB | PLB | ||

24.1 | 12.7 | - | PLB | PLB | PLB | PLB | PLB | ||

5 1/2 | 14 | 139.7 | 6.2 | PS | - | - | - | - | - |

15.5 | 6.98 | PSLBE | - | - | - | - | - | ||

17 | 7.72 | PSLBE | PLBE | PLBE | PLBE | PLBE | - | ||

20 | 9.17 | - | PLBE | PLBE | PLBE | PLBE | - | ||

23 | 10.54 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

26.8 | 12.7 | - | - | - | P | - | - | ||

29.7 | 14.27 | - | - | - | P | - | - | ||

32.6 | 15.88 | - | - | - | P | - | - | ||

35.3 | 17.45 | - | - | - | P | - | - | ||

38 | 19.05 | - | - | - | P | - | - | ||

40.5 | 20.62 | - | - | - | P | - | - | ||

43.1 | 64.14 | - | - | - | P | - | - | ||

6 5/8 | 20 | 168.28 | 7.32 | PSLB | |||||

24 | 8.94 | PSLBE | PLBE | PLBE | PLBE | PLBE | - | ||

28 | 10.59 | - | PLBE | PLBE | PLBE | PLBE | - | ||

32 | 12.06 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

7 | 20 | 177.8 | 6.91 | PS | |||||

23 | 8.05 | PSLBE | PLBE | PLBE | PLBE | - | - | ||

26 | 9.19 | PSLBE | PLBE | PLBE | PLBE | PLBE | - | ||

29 | 10.6 | PLBE | PLBE | PLBE | PLBE | ||||

32 | 11.51 | PLBE | PLBE | PLBE | PLBE | ||||

35 | 12.65 | PLBE | PLBE | PLBE | PLBE | PLBE | |||

38 | 13.72 | PLBE | PLBE | PLBE | PLBE | PLBE | |||

7 5/8 | 26.4 | 193.67 | 8.33 | PSLBE | PLBE | PLBE | PLBE | - | - |

29.7 | 9.52 | - | PLBE | PLBE | PLBE | PLBE | - | ||

33.7 | 10.92 | - | PLBE | PLBE | PLBE | PLBE | - | ||

39 | 12.7 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

42.8 | 14.27 | - | PLB | PLB | PLB | PLB | PLB | ||

45.3 | 15.11 | - | PLB | PLB | PLB | PLB | PLB | ||

47.1 | 15.88 | - | PLB | PLB | PLB | PLB | PLB | ||

8 5/8 | 24 | 219.08 | 6.71 | PS | - | - | - | - | - |

28 | 7.72 | - | - | - | - | - | - | ||

32 | 8.94 | PSLBE | - | - | - | - | - | ||

36 | 10.16 | PSLBE | PLBE | PLBE | PLBE | - | - | ||

40 | 11.43 | - | PLBE | PLBE | PLBE | PLBE | - | ||

44 | 12.7 | - | PLBE | PLBE | PLBE | PLBE | - | ||

49 | 14.15 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

9 5/8 | 36 | 244.48 | 8.94 | PSLB | - | - | - | - | - |

40 | 10.03 | PSLBE | PLBE | PLBE | PLBE | - | - | ||

43.5 | 11.05 | - | PLBE | PLBE | PLBE | PLBE | |||

47 | 11.99 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

53.5 | 13.84 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

58.4 | 15.11 | - | PLB | PLB | PLB | PLB | PLB | ||

10 3/4 | 40.5 | 273.05 | 8.89 | PSB | - | - | - | - | - |

45.5 | 10.16 | PSBE | - | - | - | - | - | ||

51 | 11.43 | PSBE | PSBE | PSBE | PSBE | PSBE | - | ||

55 | 12.57 | - | PSBE | PSBE | PSBE | PSBE | - | ||

60.7 | 13.84 | - | - | - | PSBE | PSBE | PSBE | ||

65.7 | 15.11 | - | - | - | PSB | PSB | PSB | ||

113/4 | 47 | 298.45 | 9.53 | PSB | - | - | - | - | - |

54 | 11.05 | PSB | - | - | - | - | - | ||

60 | 12.42 | PSB | PSB | PSB | PSB | PSB | PSB | ||

13 3/8 | 48 | 339.72 | 8.38 | - | - | - | - | - | - |

54.5 | 9.65 | PSB | - | - | - | - | - | ||

61 | 10.92 | PSB | - | - | - | - | |||

68 | 12.19 | PSB | PSB | PSB | PSB | PSB | - | ||

72 | 13.06 | - | PSB | PSB | PSB | PSB | PSB | ||

16 | 75 | 406 | 11.13 | PSB | - | - | - | - | - |

84 | 12.57 | PSB | - | - | - | - | - | ||

109 | 16.66 | P | P | P | - | P | P | ||

20 | 94 | 508 | 11.13 | PSLB | - | - | - | - | - |

30 | 96 | 762 | 16.13 | PSLB | - | - | - | - | - |

P-Plain end; S-Short round thread; L-Long round thread; B-Buttress thread; E-Extreme line; | |||||||||

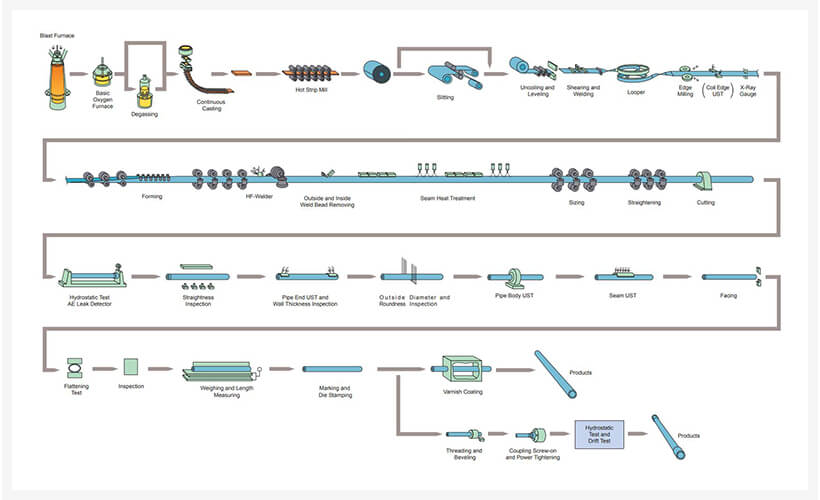

Manufacturing process of API casing

Steel ingot heating → hydraulic punching → reheating → extension → periodic rolling → reheating → sizing → cooling → straightening → pipe cutting → inspection

1. An annular heating furnace is required for ingot heating;

2. Punching and reheating with the hydraulic press;

3. The oil casing plant uses a two-roller guide plate extension machine for extension;

4. Re-use a disc heating furnace for periodic rolling, and use a non-entry furnace for reheating, cooling, straightening, pipe cutting, and inspection.

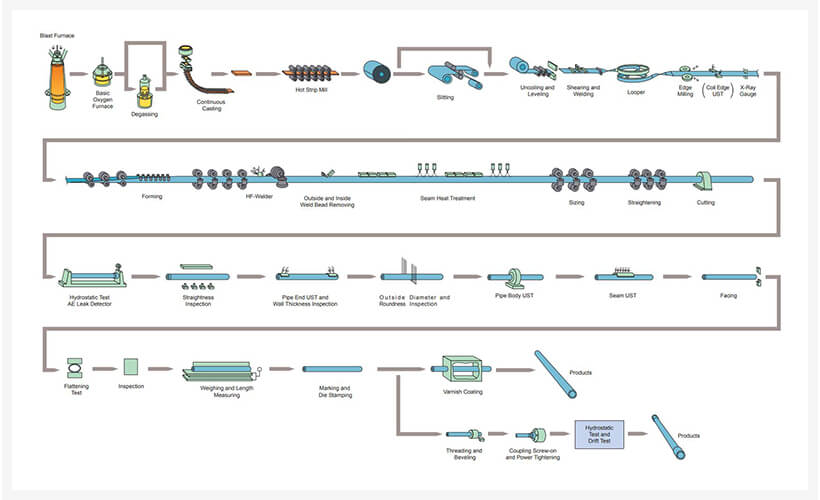

Manufacturing process of API casing

Steel ingot heating → hydraulic punching → reheating → extension → periodic rolling → reheating → sizing → cooling → straightening → pipe cutting → inspection

1. An annular heating furnace is required for ingot heating;

2. Punching and reheating with the hydraulic press;

3. The oil casing plant uses a two-roller guide plate extension machine for extension;

4. Re-use a disc heating furnace for periodic rolling, and use a non-entry furnace for reheating, cooling, straightening, pipe cutting, and inspection.

Standard of API casing

API 5L, API 5CT, ASTM 53, EN10217, DIN 2458. IS 3589, JIS G3452, BS1387

Standard of API casing

API 5L, API 5CT, ASTM 53, EN10217, DIN 2458. IS 3589, JIS G3452, BS1387

Application of API casing

Oil well extracting

Borehole

Borewell

Application of API casing

Oil well extracting

Borehole

Borewell

About Us / News / Product / Project / Quality Assurance / Service / Contact Us